Energy prices keep climbing, and argon costs have jumped over 30 % in two years. 2026 building codes will demand U-values that old equipment simply cannot deliver reliably. Every square meter you produce either adds profit or quietly drains it. The fastest way to flip that equation is to modernize the three decisive stations of your insulating glass production: gas filling, spacer application, and sealing.

Why Is Your Insulating Glass Line Draining Profits in 2026?

Rising electricity tariffs and stricter energy standards hit every factory hard. Horizontal lines waste large amounts of argon because gas fills from the side and escapes easily. Manual spacer bending creates cold bridges and air bubbles, while traditional two-component sealing often leaves tiny leaks that destroy dew-point performance within a few years. The result is higher argon consumption, more electricity for compressors and blowers, and lost rebates when units fail certification tests.

One company that has focused exclusively on this challenge for over 15 years is Wentrica. From their 10 000 m² modern factory they build fully automatic lines using only European core components while keeping prices realistic for growing factories. The solution lies in three targeted upgrades that directly eliminate these losses.

Optimize Gas Filling for Maximum Efficiency

Vertical processing changes the entire gas-filling game. Glass stands upright, argon enters from the bottom and pushes air upward, so filling efficiency reaches 93 % and higher with almost no waste.

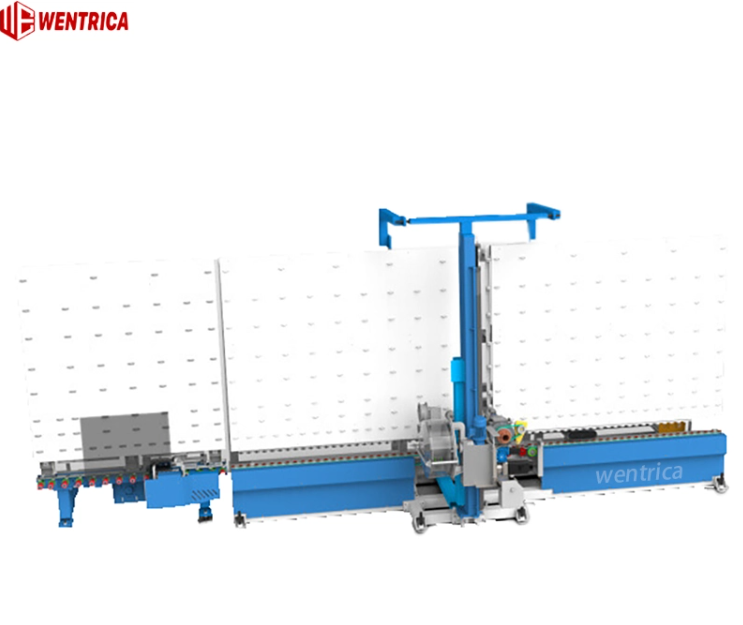

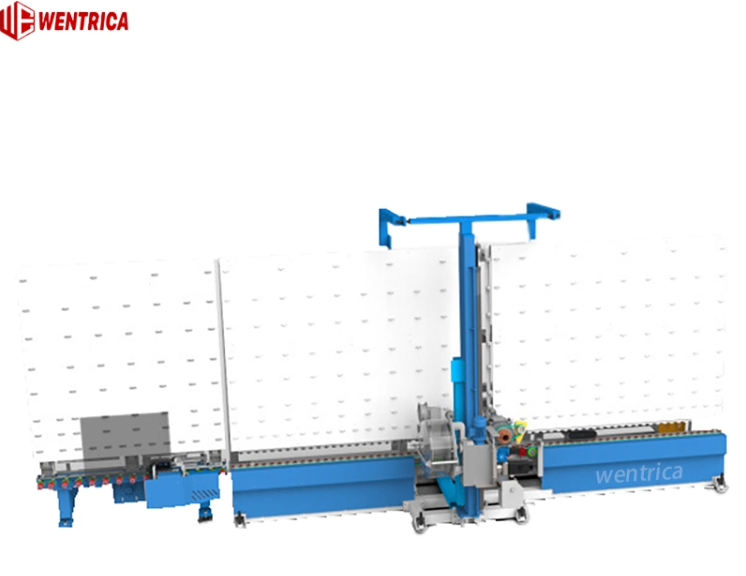

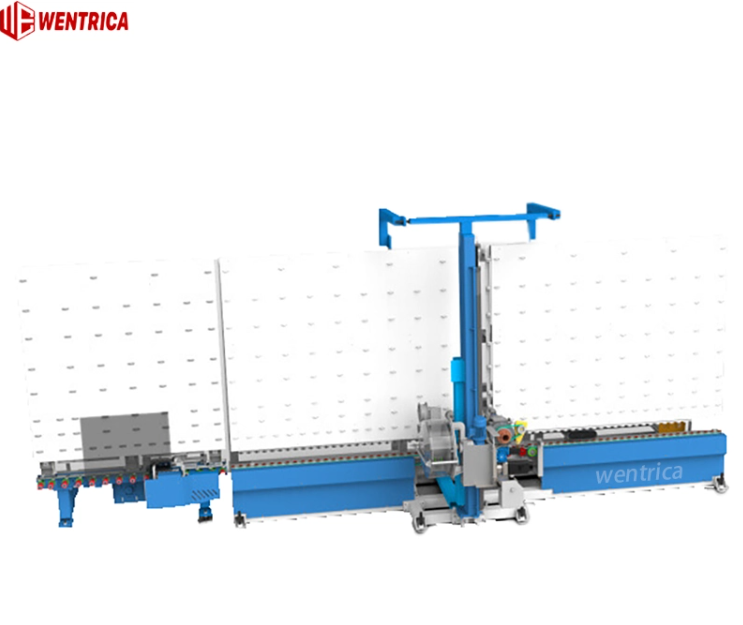

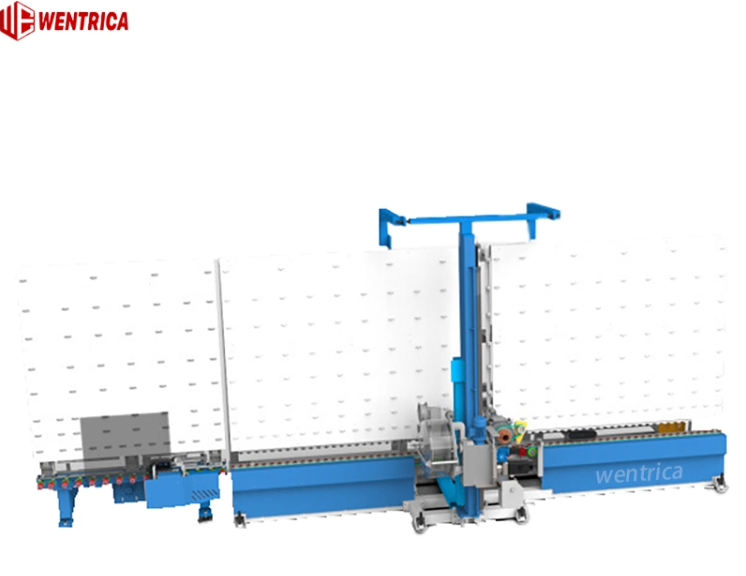

Tip 1: Adopt Vertical Processing to Minimize Argon Loss

The Automatic Vertical Insulating Glass Production Line handles the entire flow automatically with telescopic belts and dust-free environment. Factories switching from horizontal lines typically cut argon usage by 30 % to 40 % from the very first week. Dust stays out and quality stays in.

Tip 2: Implement Online Filling with Real-Time Monitoring

Sensors watch every second. Built-in sensors and Siemens PLC control stop the cycle only when the required concentration is reached. This eliminates guesswork, prevents overfilling, and guarantees every unit meets the strictest 2026 U-value standards without reworking.

Tip 3: Leverage Precision Pressing for Leak-Proof Units

Independent suction cups and automatic thickness detection guarantee perfect edge alignment before the press closes. The result is zero edge offset, no gas migration, and U-value stability that lasts decades.

Upgrade to Warm-Edge Spacers for Thermal Performance

Aluminum spacers act as thermal bridges and raise the overall U-value of the window. Flexible warm-edge spacers eliminate that bridge completely and improve the psi value immediately.

Tip 4: Transition from Aluminum to Flexible Spacers Immediately

Make the change now. Switching reduces linear heat loss by 15 % to 20 %. The payback period through energy savings and higher selling prices is usually under twelve months.

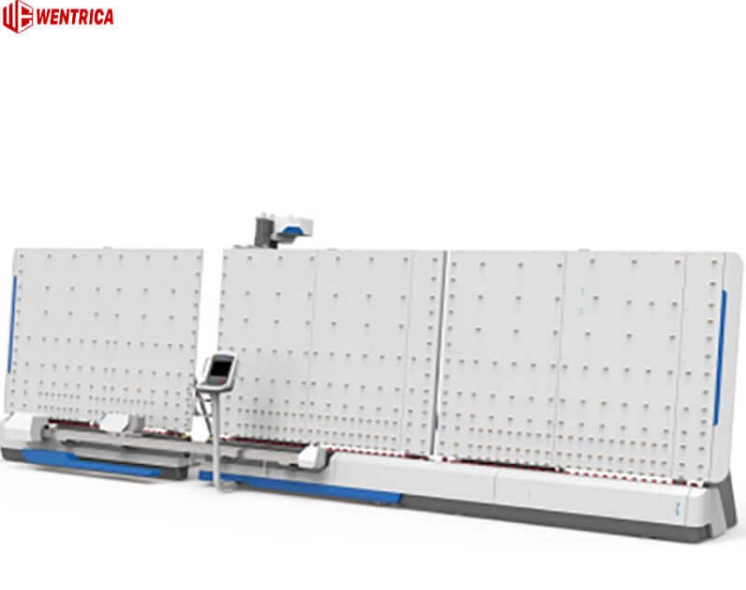

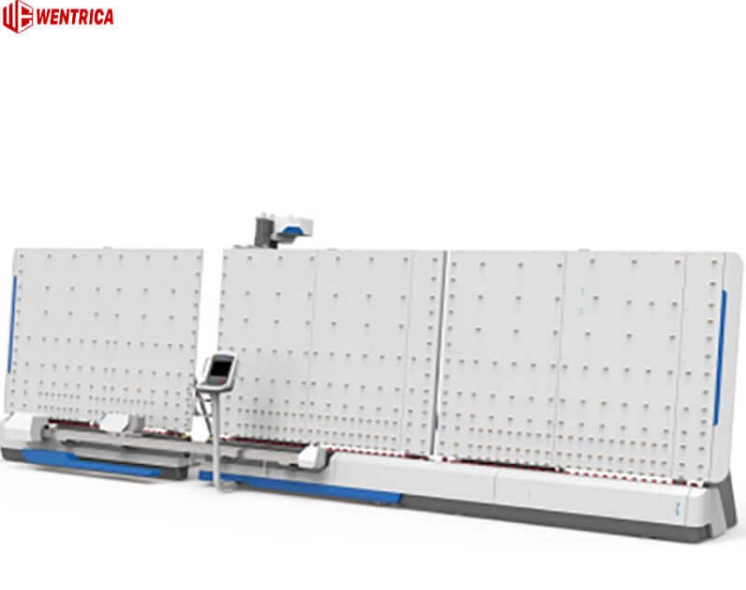

Tip 5: Automate Application to Eliminate Manual Errors

The Automatic Super Flexible Spacer Applicator uses V-blade cutting and built-in waste recycling to produce perfect corners on rectangles and shaped units without bubbles or stretching. Labor drops by 70 % and quality becomes 100 % repeatable.

Tip 6: Enable Profitable Triple Glazing Production

Triple units used to be slow and risky. Once spacer application is fully automatic, adding the third lite takes only minutes instead of hours. Triple units suddenly become a realistic high-margin product instead of a headache.

Achieve Durable Sealing to Prevent Future-Proof Your Units

Poor secondary sealing remains the number-one reason units lose argon over time. Single-component hot-melt applied robotically creates a permanent, void-free barrier.

Tip 7: Shift to Single-Component Hot-Melt Over Polysulfide

Hot-melt flows better, cures faster, and forms a completely homogeneous seal. Dew-point failure rates drop below 0.5 %, protecting both your reputation and your argon investment.

Tip 8: Invest in Robotic Precision for Consistent Seals

The Automatic Hot Melt Sealing Robot covers every millimeter evenly, regardless of glass size or shape. Manual corner touching becomes unnecessary and seal quality becomes identical on unit one and unit ten thousand.

Tip 9: Monitor Temperature for Optimal Adhesion

Precise heating zones prevent cold spots and overheating. This reduces energy consumption at the sealing station by up to 25 % while delivering perfect adhesion strength every cycle.

Tip 10: Calculate Your Exact Savings Before You Buy

Energy and argon prices will only move in one direction in 2026: up. Every factory that still runs horizontal filling, aluminum spacers, and manual sealing quietly gives away margin on every square meter shipped. When you replace those three stations with modern vertical gas filling, warm-edge automation, and robotic hot-melt sealing, the drop in argon consumption, electricity usage, and rework is immediate and permanent. Most plants recover the full investment through lower operating costs long before the warranty expires, and many qualify for new energy-efficiency rebates on top.

Why Forward-Thinking Buyers Select This Equipment in 2026

European components deliver daily reliability. The factory provides free layout design within 24 hours and lifetime remote diagnostics, so downtime almost disappears. Spare parts reach any continent in 48 hours. Early 2026 delivery slots are still open for complete lines that combine the three machines above.

Start saving today. Contact the team Wentrica and receive your customized proposal before the next price increase hits.

FAQ

Q1: How much argon can a vertical line actually save?

A: Most factories reduce argon consumption by 30 % to 40 % from day one because upward filling creates almost zero turbulence.

Q2: Will flexible spacers work on shaped and triple units?

A: Yes. Automatic V-blade applicators bend and cut perfectly on rectangles, circles, and triple glazing without manual intervention.

Q3: How long does it take to recover investment in a new sealing robot?

A: Typical payback is 14 to 22 months through lower sealant waste, zero rework, and reduced heating energy.

Q4: Can these machines meet the requirements in Europe and North America?

A: Yes. Online gas filling above 93 %, warm-edge spacers, and robotic hot-melt sealing routinely deliver U-values of 0.8 or lower in double and triple units.

Q5: What support is provided after purchase?

A: Lifetime remote diagnostics, 48-hour spare-parts delivery worldwide, and free layout optimization before installation.