Safety in glass installation depends on close following of physical laws and engineering rules. Equipment for costly materials like tempered or insulating glass must turn complex physics into steady suction strength. Wentrica serves as a professional maker of strong glass handling tools. The company offers exact-built systems from their modern plant. These ensure each lift follows strict global safety and lasting rules.

Global Safety Standards for Vacuum Lifting

Meeting technical needs for lifting tools makes sure site machines hit a common base for risk control. Standards cover details from steel frame thickness to vacuum hold time in power loss.

EN 13155 European compliance

This rule sets needs for movable load lifting parts. It requires mechanical strength to handle twice the work load limit. Vacuum lifters must include a backup safety tool or alert system. These prevent load drops.

ASME B30.20 safety margins

This key U.S. rule covers design, setup, and checks for hook-below lifting devices. It demands a strong safety factor in frame parts. Clear tags for rated load help avoid worker mistakes.

CE machinery directive requirements

CE mark shows the tool meets basic health and safety needs in Europe. It checks electrical parts, vacuum pumps, and frame welds. These must perform steady in work settings.

Critical Physics of Static Load Stability

Static load stability means force balance on the glass sheet when still. Lifter frame design must offset gravity pull. It spreads lift force over the full material surface.

Four to one safety factor

Lifting rules often call for a 4:1 safety rate. Parts must hold four times the top rated weight. This covers sudden force shifts or slow material wear over time.

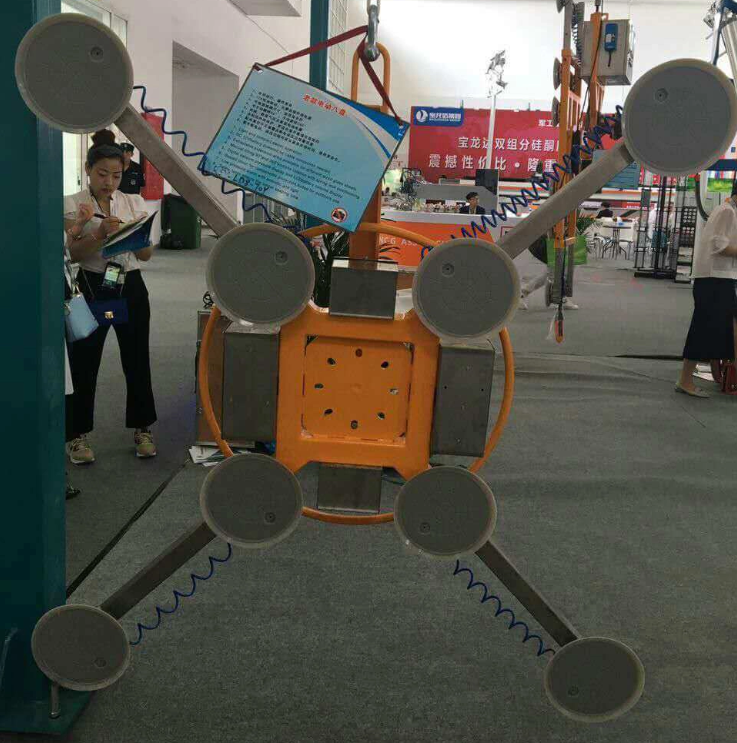

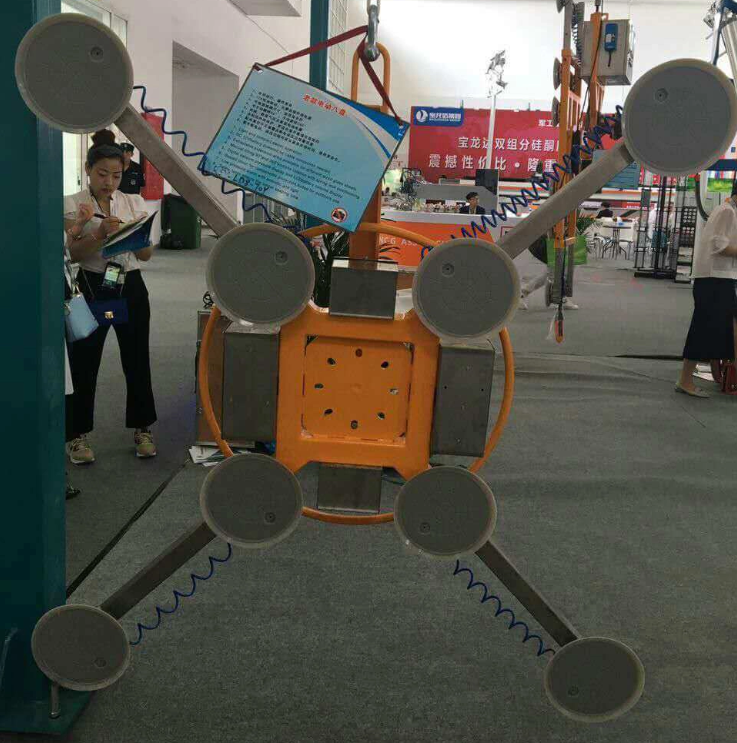

Structural integrity of X type frames

X-shape setup gives better twist strength than straight forms. It suits big building panels well. The X Type Electric Vacuum Glass Lift Elevator uses this shape. It spreads pressure even and cuts glass bend risk.

Load distribution across multiple suction pads

Load distribution across multiple suction pads

Multiple pads spread vacuum force away from one spot. This guards weak glass layers. Each pad has its own control valve. These allow setup changes for glass form.

Fluid Dynamics of Vacuum Pressure Retention

Vacuum lifting creates pressure gap between air outside and space in the cup. System success rests on keeping low pressure despite small leaks.

Negative pressure thresholds for heavy glass

Systems need -0.6 to -0.9 bar vacuum for firm hold on heavy panels. A built-in gauge tracks these levels. It spots when grip peaks.

Impact of American Thomas vacuum pumps

Strong pumps form the system core. They pull air fast for quick suction. These run steady in long shifts. They avoid heat build or power drop.

Airflow management in sealed vacuum systems

Good seals block air return to the vacuum path. This keeps hold firm. Check valves and tanks store low pressure. They buffer against pump stops.

Material Science of High Friction Suction Cups

The link between tool and glass is the suction cup. Material traits set grip level. Cup features decide if it fights slide forces in upright lifts.

Silica gel coefficient of friction

Silica gel suits glass work due to high friction rate. It handles -40°C to 90°C heat range. This keeps the cup soft for tight seal in harsh weather.

Non-marking surface adhesion properties

Top cups avoid residue or marks on glass. This matters for fine curtain walls and U-glass. Looks stay key in these uses.

Thermal resistance in extreme weather conditions

Site work faces hot and cold shifts. These change air density and rubber flex. Strong lifters use steady materials. They hold size and grip in wide heat spans.

Mechanical Engineering of Rotation and Tilting

Shifting glass from flat rack to upright wall needs complex moves. Physics rules say rotations must keep gravity center in the stable base area.

Center of gravity alignment during 360 rotation

Keeping gravity center on the turn axis stops wild swings. Exact bearings and even arm reach give smooth shifts. Operators need less force for this.

Torque management for 90 degree flipping

Turning heavy glass makes strong torque. The frame must take this load. The Line Type Electrical Glass Lifter handles it. Manual turn and flip parts suit careful work.

Static friction vs kinetic movement safety

Move friction to hold glass tops static needs. Brakes and lock pins keep it in place after turns. This ensures steady spots. The table below compares key physical traits for project needs. It shows safety and work flow in top lifting tools.

Physical Parameter | Technical Standard / Requirement | Safety Function |

Vacuum Pressure (P) | -0.6 bar to -0.9 bar | Ensures base suction grip strength |

Static Safety Factor | 4:1 (Structural Load Limit) | Prevents structural collapse under stress |

Emergency Buffer Time | $\ge$ 15 Minutes (Power Off) | Provides escape window during failure |

Working Temperature | -20°C to +90°C | Maintains material elasticity and seal |

Friction Coefficient ($\mu$) | $\ge$ 0.5 (on clean glass) | Prevents vertical slippage during tilt |

These figures set required levels for work-grade glass tools. Following them lets gear handle site factors like wind on walls or wet glass faces.

Safety Advantages of Wentrica Equipment

Picking proper tools means a maker that blends physics into easy-use forms. Wentrica joins tough materials and electronic checks. This guards workers and glass alike.

Integration of X type electric remote control

This setup lets operation from up to 50 meters away. It keeps staff out of fall paths. Electric turn and tilt give even moves. These shield glass from sharp jolts.

Flexibility of Line type manual rotation systems

Linear form fits small glass or inside shifts. It gives a small tool for tight spots. Big X-frames may not fit there well.

Proprietary 15 minute power off protection technology

Systems beat safety rules with 15-minute vacuum hold after power cut. This gives time to lower load or clear the zone safely. Experts at the Wentrica Contact Us page offer tech help.

FAQ

Q1: How long will the suction cups hold the glass if the power fails?

A: Professional equipment is designed to hold the glass for a minimum of 15 minutes through a vacuum reservoir and check valves.

Q2: Can these lifters handle materials other than glass?

A: Yes, they are physically capable of lifting any non-porous flat material, including steel plates, granite, and marble.

Q3: What is the benefit of a remote control system on a glass lifter?

A: Remote control allows the operator to stand at a safe distance and provides a better vantage point for precise positioning during curtain wall installation.

Q4: Do the suction cups leave permanent marks on the glass?

A: No, the use of high-quality silica gel ensures the cups are non-marking and safe for use on all types of processed glass.

Q5: Why is an X-shaped frame better for large glass?

A: An X-frame provides more points of contact across a wider area, which significantly reduces the physical stress and bending on large sheets.

Load distribution across multiple suction pads

Load distribution across multiple suction pads