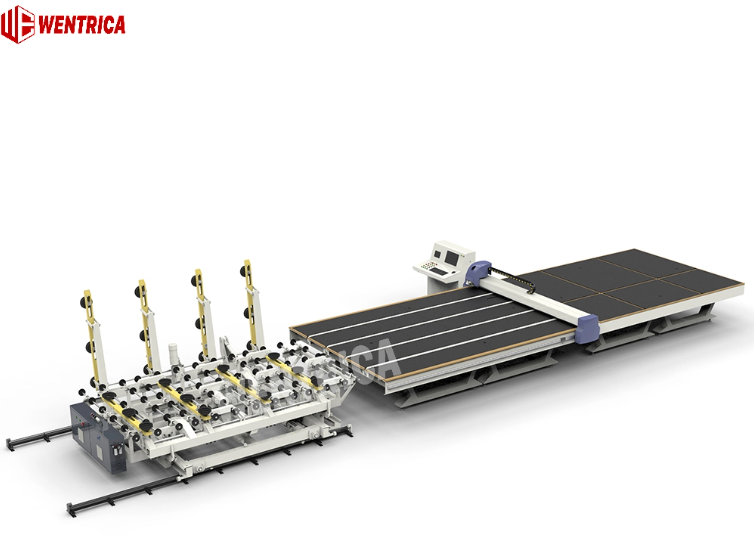

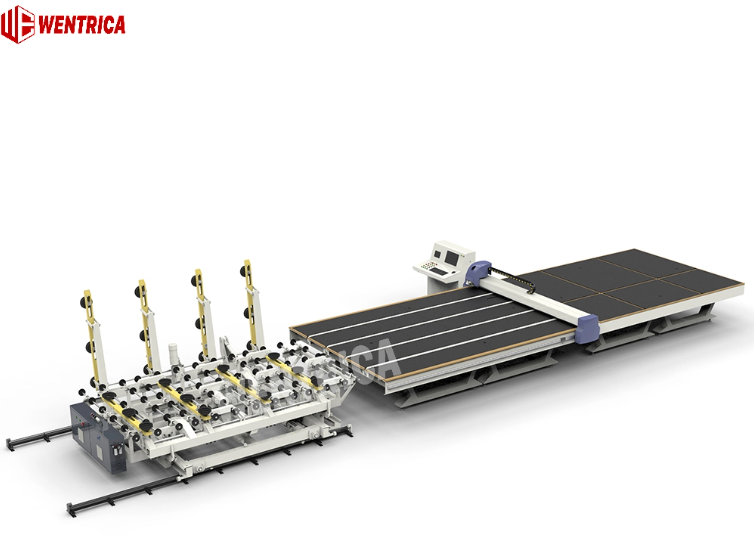

Glass work in factories demands accuracy and steady flow. A high-speed CNC glass cutting machine marks a major outlay for smoother operations in your line. To keep this gear's sharp servo handling and smart setup steady for long periods, follow a strict care routine. Wentrica is a manufacturer specializing in advanced glass machinery. Their state-of-the-art factory produces high-performance solutions that integrate cutting-edge technology with industrial durability, ensuring your glass processing facility achieves maximum ROI through reliable, world-class engineering.

Tip 1: Prioritize Mechanical Component Lubrication and Cleaning

A CNC unit's core strength relies on easy motion among its active sections. Quick runs create rub and warmth. These factors can cause early damage to the drive setup. Proper care demands a firm clean and oil routine. This approach wards off such issues effectively.

Regular lubrication of guide rails

Apply dedicated oil to the straight guide rails and tooth bars each day. This action lowers the rub factor in fast shifts. As a result, servo motors avoid extra load. Moreover, the beam system holds its true path over time. You achieve consistent results in every task.

Removal of glass powder and debris

Glass grit serves as a harsh scraper that harms slide block gaskets. Use a suction device or pressed air to wipe the work surface and drive routes after each session. Such steps block small grains from reaching inner drive units. This practice preserves overall function and cuts downtime.

Inspection of the transmission system

Examine the timing belt tightness and gear mesh at set intervals. A slack strap or shifted tooth bar triggers position errors in swift starts. Consequently, this affects size limits on your building or factory glass items. Regular checks help maintain product standards without fail.

Tip 2: Ensure Precision of the Cutting Head and Tooling

The cut head forms the key link between the unit and the stock. Proper upkeep of this part guarantees that the High-Speed CNC Glass Cutting Machine produces neat snaps. No edge chips or surface splits occur. This reliability supports efficient workflows.

Blade pressure calibration via intelligent system

Employ the inner smart control to track and adjust cut force. Accurate force levels avoid excess load on air units. They also prolong the tool's active span. At the same time, edge finish remains consistent. Operators benefit from smoother daily runs.

Routine replacement of consumable parts

Swap cut discs and outlets at the builder's advised periods. Used items demand greater force for scoring. This raises pane split chances. It also burdens the head assembly unduly. Timely changes ensure safe and precise operations throughout.

Verification of the oil injection system

Verify that score oil reaches the tool end without blocks. Adequate oil at the contact spot eases heat strain on the pane. It halts wheel lock-ups too. Such care is crucial for sustained fast output. Daily reviews keep performance optimal.

Tip 3: Maintain the Electrical and Intelligent Control System

The power panel contains the core logic of your tool. In an advanced model like the WE-4228 CNC Full Automatic High Speed Glass Cutting Machine, shielding circuit parts from site threats proves vital. It averts breakdowns and file losses. Thus, production continues without interruptions.

Dust protection for the control cabinet

Seal the power panel lids firmly in use. Grit buildup on boards sparks heat or faults. Hence, employ a gentle brush or mild air flow for inner wipes in a safe area. This method sustains clear function. It prevents unexpected halts during shifts.

Stability of power supply voltage

Your site should deliver even power to the unit. Voltage shifts harm delicate servo units and guides. Therefore, install a solid stabilizer. It protects the smart circuit base. Equipment longevity improves as a result.

Software updates and data backup

Save cut details and program configs frequently. Update the core code on a routine basis. This grants access to new speed methods. It also shields against step flaws in tough form tasks. Backed files ensure quick recovery if needed.

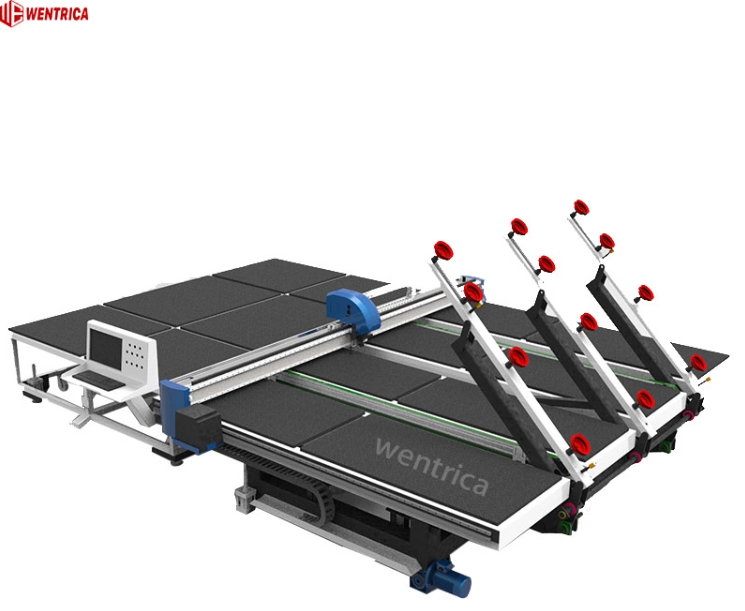

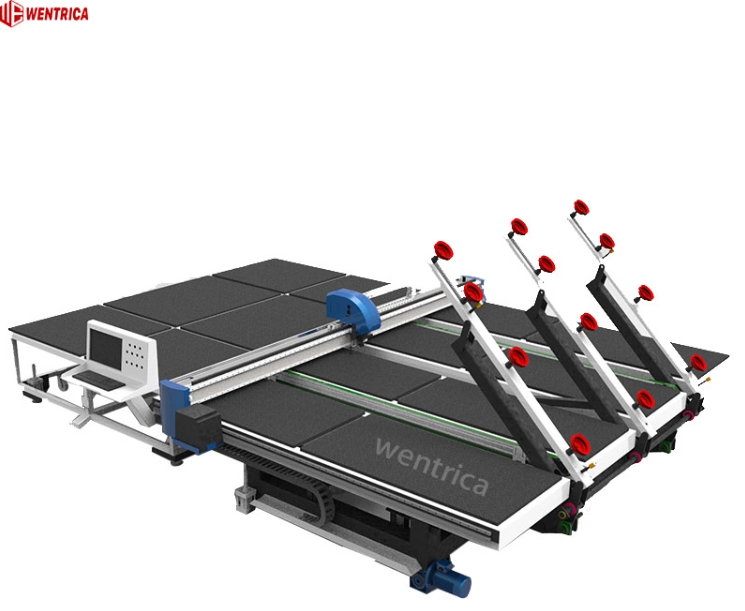

Tip 4: Monitor the Pneumatic and Loading Systems

In total auto setups, the load arm and cut platform need fluid ties. The air network drives items from grip pads to snap rods. Focus upkeep here to preempt problems. Seamless action supports nonstop runs.

Daily check of air pressure stability

The Automatic Glass Loading And Cutting Integrated Machine depends on steady air force for safe pane lifts. Track the gauges each day. Keep grip strength in the approved zone. This avoids slips. Handling proceeds securely.

Filtration and drainage of the air compressor

Moisture in air paths rusts valve coils and rams. Empty the filters and holds daily. Only pure dry air should feed the unit's air loop. Clean paths endure longer. Flow remains unobstructed.

Inspection of vacuum suction cups

Scan the pad rubbers for splits, stiffening, or specks. Uphold their wholeness to block air escapes. Secure pane shifts from hold shelf to cut bed follow. No mid-path drops occur. Reliability in transport holds firm.

Tip 5: Professional Calibration and Operational Environment

Site conditions and frame balance shape the tool's final sharpness. Ongoing jolts and base sinks alter the form gradually. Periodic expert resets become necessary. This sustains peak accuracy over extended use.

Horizontal level re-calibration

Test the frame base flatness with an exact level device. Maintain full evenness to curb lopsided rub on rollers. CAD-guided cut routes stay true. No drift affects daily precision.

Cooling system maintenance for motors

Wipe the fan coolers and heat traps on servo drives routinely. Heat excess drops drive output. It may trigger heat stops. Such events break schedules. Wire coils face harm risks. Regular cleans avert these threats.

Scheduled professional inspections by Wentrica technicians

Hire skilled pros for a yearly full scan. Expert checks spot small shifts or circuit fade unseen in routine work. Gear reaches max output. Hidden flaws stay caught early. Operations run at full strength.

Wentrica Company Product Advantages

Selecting Wentrica tools gives your site a base of trust and forward design. Their units feature robust frame bases and sturdy beams. These offer firm support for quick factory tasks. Accuracy endures without cuts. Dependable performance follows suit.

Sharp servo systems enable work on boxes, curves, and tricky forms. No solid templates required. This range pairs with smart layout code. It boosts stock use and trims scraps. Wentrica stresses auto flows in load-cut setups. Work costs fall sharply. Site safety grows via less hand pane moves. Their worldwide aid web and quality pledge shield buys. Pros offer easy reach. Parts prove lasting.

FAQ

Q1: How often should I lubricate the guide rails of my CNC glass cutter?

A: You should lubricate the guide rails and gear racks every day before starting production. This minimizes friction and prevents wear during high-speed operations.

Q2: What is the main benefit of an integrated loading and cutting machine?

A: It combines two processes into one footprint. This reduces glass handling risks and saves floor space. Automated links raise total output flow.

Q3: Why is air pressure stability important for automatic glass machinery?

A: Stable air pressure ensures that vacuum suction cups maintain a firm grip on glass sheets. The cutting head applies consistent force for a clean break.