The glass processing world in 2026 calls for top-notch accuracy and quick turnaround times like never before. With demands from architectural and industrial glass getting trickier every day, old-school manual setups or separate machines just don't cut it anymore. If you want to stay ahead of the pack, your shop needs to shift toward fully connected systems. These setups cut down on wasted material and sloppy mistakes from people. Wentrica steps in here with solid engineering know-how and purpose-built gear.

Defining the Unified Glass Pre-processing Line

Think of a unified glass pre-processing line as one smooth, linked setup. Cutting, edging, and washing all run together without breaks. Everything shares the same smart controls. In the past, folks handled glass in batches. They moved pieces by hand between stations and sometimes stored them in between. That approach wasted time and risked bumps or scratches. Now, on a unified line, raw sheets go in at one end. They move straight through each key prep step. No extra waiting around. This setup lowers chances of damage from handling. It also helps deliver glass that hits the tight quality marks needed before tempering or laminating kicks in.

Operational Efficiency Gains through Intelligent Cutting

The cutting part acts as the entry point for the whole line. In today's busy plants, how well you cut sets the pace for output and how much usable glass you get from each sheet. Older semi-automatic cutters often needed physical templates. Those slowed things down. Switching to digital methods lets you switch shapes and sizes on the fly.

Precision CNC Path Optimization

The High-Speed CNC Glass Cutting Machine relies on clever software. It figures out the smartest way to arrange cuts on every raw sheet. This boosts how much material you actually use. It slashes leftover scraps too. Less waste means lower costs right from the start.

High-Speed Automated Material Flow

Conveyors move sheets automatically from the loading spot straight to the cutting table. No more workers lugging heavy pieces by hand. This keeps everything moving at a steady clip. The pace matches what the CNC head can handle without rushing or stalling.

Dynamic Production Scheduling Integration

The control setup lets you jump between different jobs smoothly. You don't have to halt the machine. Feed in orders for squares, circles, or odd irregular forms one after another. The line stays busy all shift long. Operators simply load up designs. The system handles the rest with minimal fuss.

Quality Standards Enhancement in Edge Processing

Once cutting finishes and pieces break out, edges stay razor-sharp. Tiny cracks hide in there too. Those flaws can cause breaks later during heating. Adding a precise grinding step fixes that. Every piece comes out stronger and better-looking. This matters a lot for fancy architectural jobs where looks and safety count.

Multi-Axis Motorized Precision Grinding

Machines with several grinding motors tackle edges and corners at once. They knock off sharp bits fast. This gives a uniform finish that lines up with tough industry rules for safety and looks.

Automated Edge Profiling Consistency

A Programmable Logic Controller, or PLC, keeps grinding pressure and speed steady across every sheet. No wild swings like you see with hands-on methods. The result? Edges match perfectly batch after batch. Fewer rejects mean happier customers.

Micro-crack Formation Risk Mitigation

Good grinding heads wipe out stress spots left from cutting. They smooth the profile nicely. That simple fix bumps up how well glass survives tempering. Fewer failures show up downstream.

Cleanliness and Surface Preparation Excellence

The last prep step clears away every bit of dirt or residue. After edging, glass picks up fine powder, coolant traces, and smudges. Any leftover junk can scratch during tempering or ruin coatings. A horizontal washer scrubs everything clean. Then it dries the surface fast. Glass exits ready for whatever comes next.

High-Speed Particulate Debris Removal

The High-Efficiency Horizontal Glass Washing Machine blasts high-pressure water and uses special brushes. They lift off tiny glass dust and sticky residues. This deep clean protects the clear look you need in finished products.

Advanced Rapid Drying Integration

Strong air knives paired with heat blow away moisture from both sides. Drying happens quick. No water marks form. You can handle or stack sheets right away without worry.

Scalable Large-Format Glass Cleaning

The horizontal layout takes on big widths and lengths easily. It fits whatever panel sizes your projects throw at it. No need to swap gear when jobs change. This flexibility keeps your line humming through varied orders.

Product Advantages of Wentrica Machinery

Picking the right tools ranks as one of the biggest calls when updating your setup. Wentrica builds gear tough enough for daily heavy use. Yet it handles delicate high-clarity glass gently too. These machines fit smoothly into current workflows while hitting precision targets.

High-Speed CNC Glass Cutting Machine

This unit packs an intelligent control system. It delivers fast acceleration and spot-on positioning. Builders designed it especially for architectural work. There, quick cuts and shape exactness drive performance.

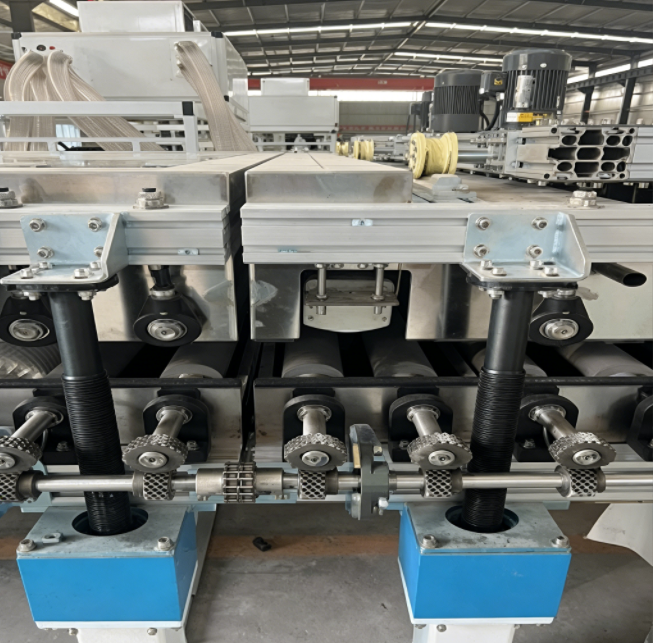

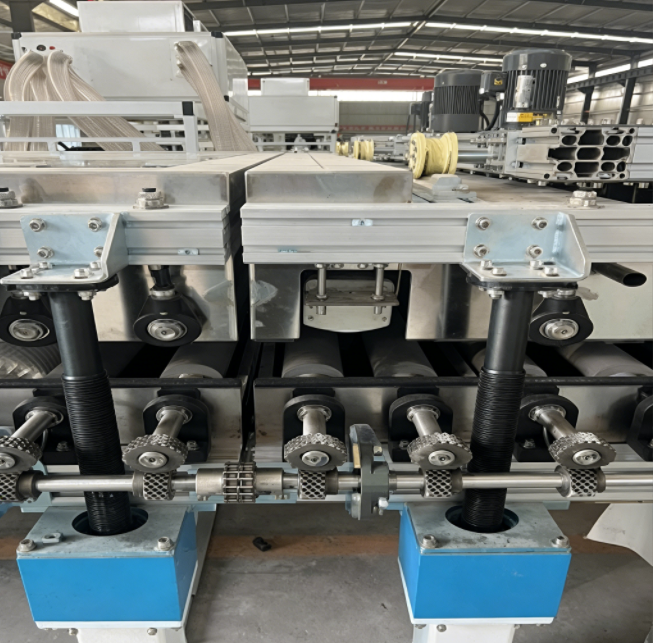

Automatic Glass Edge Grinding Machine (WEZ9325P)

The Automatic Glass Edge Grinding Machine comes with 9 motors and a PLC setup. It produces clean 45-degree miter edges along with straight ones. Operators make very few tweaks once running. The process stays reliable shift after shift.

High-Efficiency Horizontal Glass Washing Machine

This washer focuses on saving energy while drying fast. Its sturdy build and smart water handling make it dependable in high-output shops. It tackles big runs without hiccups.

Future-Proofing Your Factory with Wentrica Solutions

Updating your plant goes beyond buying boxes of metal. You need a solid partner with real experience. Wentrica runs a dedicated factory loaded with modern tools. Every machine meets global benchmarks. By zeroing in on these core prep stages, you build a strong base for your whole operation. Curious about rolling these out? Head to the Contact Us section. Talk specifics with the team there. They handle technical details and custom fits.

FAQ

Q1: Why is the cutting, edging, and washing sequence considered the standard for glass processing?

A: These three steps cover the basic prep any glass needs before tempering, coating, or laminating. Linking them creates glass that's clean, sized right, and tough enough structurally.

Q2: How does the PLC system in Wentrica grinding machines improve production?

A: It takes over tweaking grinding settings automatically. Every sheet ends up with matching edge quality and size. Human slip-ups drop way down.

Q3: Can the CNC cutting machine handle irregular shapes without a physical mold?

A: Sure thing. The CNC pulls in digital files directly. It cuts squares, rounds, and fancy outlines. No old-school molds required.

Q4: What are the benefits of a horizontal washing machine compared to a vertical one?

A: Horizontal ones mesh better into automatic lines. They manage big or heavy sheets easier. Plus, they dry quicker and more evenly overall.

Q5: Does Wentrica provide support for setting up a complete production line?

A: Yes. They guide you on picking gear and specs. Everything meshes well in your shop setup.