In the changing global energy market, solar glass quality affects the efficiency of photovoltaic modules. A clean surface without dust and oil is the initial key step in standard glass processing. Wentrica offers full, one-stop solutions for equipment design and production in the glass deep processing sector. This article looks at how professional washing tools improve solar glass production. It also gives basic maintenance methods to support ongoing success.

Definition and Significance of Horizontal Glass Washing Machine in Solar Industry

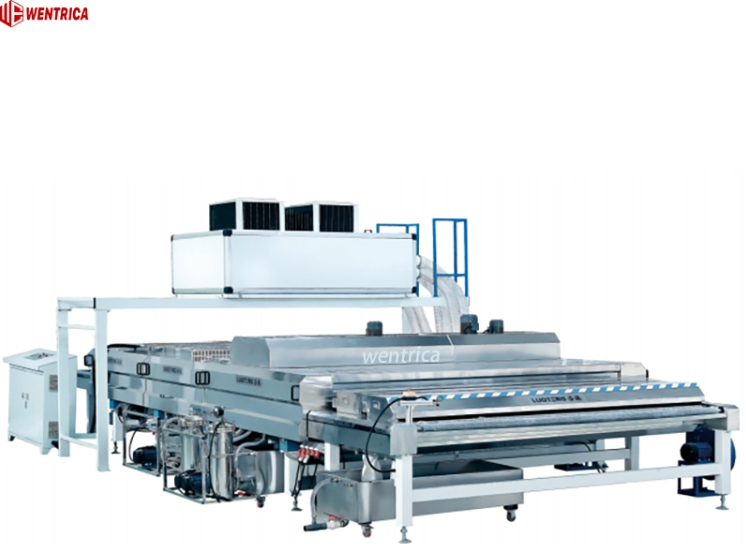

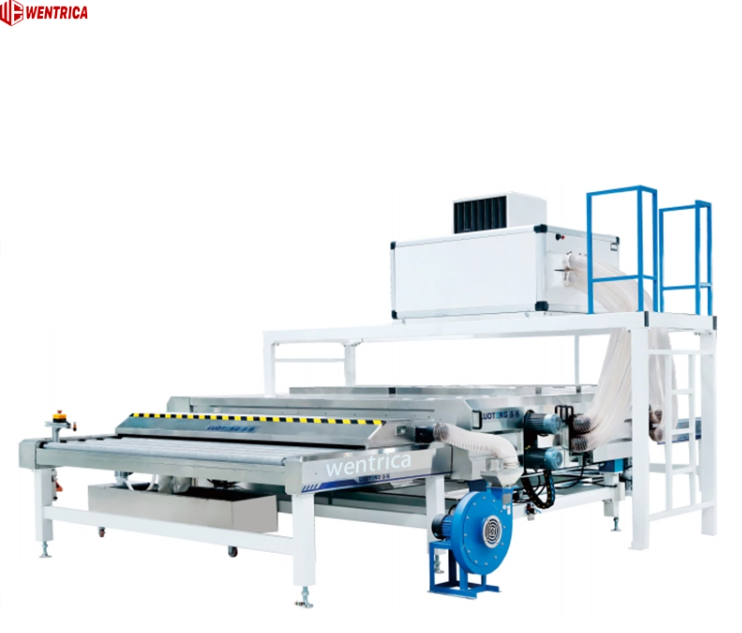

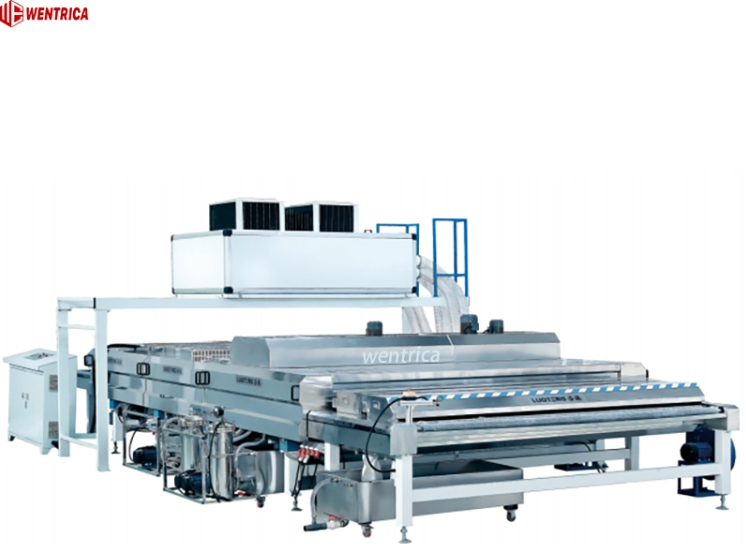

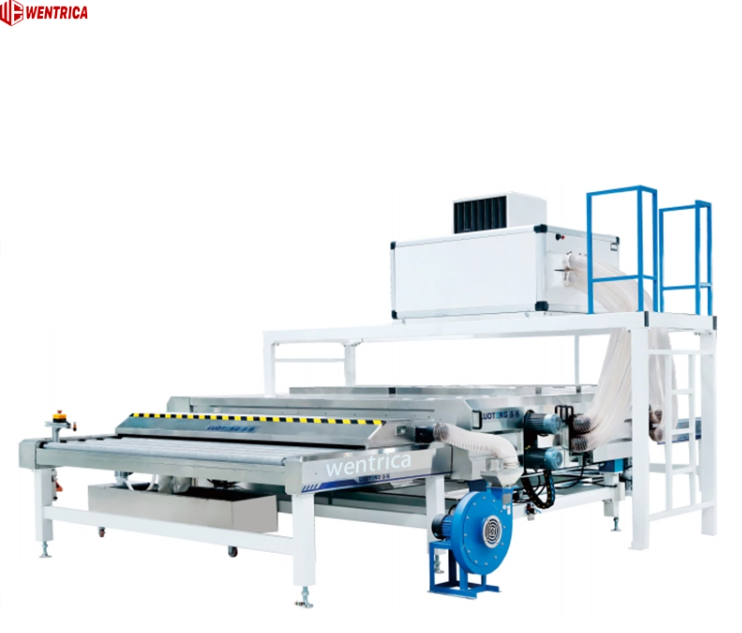

The solar glass sector needs great accuracy. Even tiny contaminants can cut light transmittance. A horizontal glass washing machine is a dedicated industrial setup. It cleans and dries flat glass sheets via a steady roller conveyor. This differs from manual or vertical cleaning approaches. The horizontal setup handles large, thin solar sheets without issues. The machine includes several parts, such as pre-spraying, brush scrubbing, and high-pressure air drying. For solar glass producers, the main aim is a spotless surface before coating or tempering. Quality washing avoids problems in later steps like laminating or insulating. Professional tools keep the glass strong and useful in fast production lines.

Core Features of Professional Solar Glass Washing Equipment

Picking the correct equipment means reviewing technical details that fit solar glass needs. Solar glass usually has special coatings or textures. These call for careful but complete handling. Current machines must mix strength with care to prevent surface harm.

High Precision Cleaning System

The cleaning area uses several pairs of brushes on stainless steel shafts. These brushes mix nylon hard types with soft ones. They remove glass powder and chemical remains well. Quality rollers from imported butyl rubber let the glass move evenly. They avoid slips or marks.

Advanced Hot Air Drying Technology

Water harms solar glass coating. Professional machines apply special aluminum alloy wind knives. These provide even, fast airflow. Built-in heating raises the air temperature. Thus, the glass dries fully before unloading.

Low-E Glass Compatibility Modules

Solar glass work often includes Low-E or other functional coatings. The High-Efficiency Horizontal Glass Washing Machine has targeted brush setups. They clean the surface without harming sensitive coatings. This flexibility suits varied production lines.

Top Performance Indicators for High Efficiency Glass Washing

To stay competitive, track certain performance measures for the washing line. These show the machine's skill in managing large workloads. They also keep steady results.

Stable Transmission Speed Control

A solid drive system employs frequency conversion for speed adjustment from 1 to 12 meters per minute. This helps match the washing with other tools like cutting or tempering lines. Steady rotation boosts the life of parts inside. It also ensures even cleaning.

Water Recycling and Filtration Efficiency

Sustainability and cost savings rely on good water handling. Professional machines have circulating water setups with glass powder filters. These filters lengthen water use. They also shield spray nozzles from blocks. So, high-pressure work continues smoothly.

Automated PLC Intelligent Interface

Current glass washers use industrial-grade Programmable Logic Controllers (PLC) and simple touch screens. This setup offers live checks of energy use and operation details. Automation cuts labor needs. It also lowers error chances in tough production runs.

Technical Specifications and Performance Data for Industrial Excellence

To optimize your production line, you must evaluate the specific mechanical capabilities of your washing equipment. Technical data serves as the foundation for operational planning, allowing you to align the machine's output with your factory's energy capacity and processing requirements. The following table details the critical parameters of the High-Efficiency Horizontal Glass Washing Machine, highlighting its heavy-duty design and high-speed processing potential.

Technical Item | Specification Details | Unit / Value |

Processing Width | Maximum cleaning capability | 2500 mm |

Glass Thickness | Versatile processing range | 3 – 25 mm |

Minimum Glass Size | Small sheet handling capacity | 400 × 350 mm |

Cleaning Speed | Variable frequency adjustment | 1 – 12 m/min |

Total Power Load | Comprehensive energy consumption | 61 kW |

Air & Water Heating | Thermal drying and washing power | 10 kW + 10 kW |

Machine Weight | Net weight for structural stability | ≈ 3800 kg |

Blower System | Variable frequency high-pressure fan | 30 kW |

These specifications demonstrate the industrial robustness of the equipment, particularly its 3800 kg self-weight which minimizes vibration during high-speed operations. By integrating a 30 kW blower system alongside 20 kW of combined heating power, you ensure that even the largest solar glass sheets emerge completely dry and ready for immediate coating. This balance of power and precision is what sets professional-grade machinery apart from standard domestic models.

Crucial Tips for Efficient Maintenance of Industrial Glass Washers

Maintenance stops sudden stops and lengthens equipment life. A strict schedule keeps all parts working well. Ignoring minor problems can cause big fixes and delays.

Daily Brush and Roller Inspection

Examine brushes each day for wear or built-up debris. Such buildup might mark the glass. Check butyl rubber rollers for cleanliness and no oil. In Wentrica machines, the cleaning area lifts 350mm. This makes checks easy and full.

Regular Water Tank Cleaning Protocol

Sediment and glass bits build in the water tank over time. Clean the tank and swap filters often to hold water quality. Fresh water stops contaminants from returning to the glass in the last rinse.

Blower and Filter Component Care

Drying work relies on clean air from the high-pressure fan. Check the air filter in the fan box for blocks by dust. Clean aluminum wind knives and keep them straight. This maintains strong, even airflow over the glass width.

Wentrica as your Partner for Solar Glass Solutions

Selecting Wentrica means putting money into proven manufacturing quality and steady service. Their factory facilities use square steel tubing and modern casting methods. They build machines for tough 24/7 industrial use. The High-Efficiency Horizontal Glass Washing Machine shows this standard. It has a waterproof build with three-layer sealing against leaks. From the rust-proof frame to high-torque motors, each part is made for lasting strength. Wentrica offers a one-year warranty and site debugging. This ensures smooth fit into facilities. For custom tech help or a quote, use their contact page. Working with a skilled maker helps solar glass production hit top global standards.

FAQ

Q1: What is the maximum glass thickness the Wentrica washing machine can handle?

A: The machine is designed to process glass thicknesses ranging from 3mm to 25mm, making it suitable for a wide variety of solar and architectural applications.

Q2: Can this machine wash Low-E coated glass without damaging the surface?

A: Yes, it features specific brush configurations and stainless steel shaft configurations designed to clean Low-E and ordinary coated glass safely.

Q3: How much space is required for the installation of the High-Efficiency model?

A: The equipment dimensions are approximately 5580 × 3340 × 900 mm, though the width may vary depending on the specific model configuration you choose.

Q4: What kind of transmission system does the machine use?

A: It utilizes gear transmission with frequency conversion speed regulation, ensuring stable rotation and an adjustable speed range of 1 to 12 meters per minute.

Q5: Is the equipment easy to maintain?

A: Yes, the cleaning and drying sections can be lifted as a whole by 350mm, providing easy access for the cleaning of rollers, brushes, and general maintenance.