If you are operating in the demanding world of architectural, industrial, or automotive glass fabrication, a fundamental question often arises during equipment upgrades: Is the premium cost of a high-speed CNC glass cutter truly justified over a standard model? The answer depends entirely on your long-term vision for capacity, material yield, and overall operational expenditure. This analysis moves beyond the sticker price to evaluate the total value proposition.

Why Are Existing Cutting Methods Limiting Your Profitability?

Many glass processors continue to rely on older, less automated cutting solutions, often leading to bottlenecks and eroded margins. If you are struggling to keep up with order volume or maintain consistent quality, your current equipment may be directly contributing to these limitations.

Slow Cycle Times Reduce Output

Older cutting machines, including semi-automatic models, often involve significant manual intervention for setup, alignment, and glass movement. As stated in industry knowledge, production efficiency of semi-automatic cutters, while higher than manual ones, still relies on pneumatic and motor-assisted kinetic energy and requires a mold for shaped glass, which inherently slows down the cycle compared to fully automated systems. This delay means you are maximizing the machine's footprint, but minimizing its actual output, limiting your daily capacity.

Inconsistent Edge Quality Requires Rework

When operating standard cutters, slight inconsistencies in the cutter head pressure or travel velocity can lead to micro-fissures or uneven edges. This lack of control necessitates further polishing or rework downstream, adding unexpected labor and time to your process. The initial cut should be the final cut, requiring machinery capable of repeatable perfection.

High Labor Dependence Increases Operating Costs

If your cutting process requires multiple operators for loading, aligning, supervising the cut, and offloading, your labor costs per square meter remain high. This reliance also introduces human error, leading to material losses and safety concerns. Fully automatic production line models significantly reduce this reliance, offering superior automation and control.

How Does a High Speed System Fundamentally Redefine Throughput?

The defining feature of a high-speed CNC cutter is not merely how fast the wheel moves across the glass, but how efficiently it manages the entire production cycle.

Accelerated Cutting Speed and Velocity

High-speed CNC systems utilize powerful servo motors and advanced transmission mechanisms to achieve rapid acceleration and high linear speeds. They can quickly transition between cutting paths without lag, maximizing the time the cutting wheel is actively engaged with the glass surface.

Minimized Non Cutting Time

In any glass fabrication line, the non-cutting tasks—such as positioning, alignment checks, and tool changes—consume valuable minutes. High-speed systems leverage synchronized automation and sensors to reduce these pauses to mere seconds, ensuring continuous flow.

Seamless Integration Into Production Lines

A key advantage is the ability of these modern systems to function as part of a larger, integrated line, leading to substantial efficiency gains.

Feature | Standard CNC Cutter | High Speed CNC Cutter |

Typical Cutting Speed | Up to 120 m/min | Up to 180 m/min |

Non-Cutting Time | Manual Alignment, Slow Homing | Sensor-Based, Near-Zero Lag |

Data Integration | Limited, often Requires Manual Input | Full CAD/ERP System Compatibility |

Transfer Speed | Moderate, Dependent on Conveyor | Synchronized with Automated Loaders |

Does Increased Speed Compromise Cutting Precision and Material Yield?

This is perhaps the most critical concern for any factory manager: does faster equal sloppier? With modern high-speed technology, the opposite is true. Speed is achieved through better engineering, not reduced quality.

Servo Motor Control Guarantees Micro Accuracy

High-speed machinery, such as the High-Speed CNC Glass Cutting Machine, relies on sophisticated servo motor control systems (often Yaskawa or similar high-precision components) to ensure the cutting head follows the exact prescribed geometry, even at high velocities. This electronic precision eliminates the mechanical play or lag common in older models.

Optimized Nesting Software Maximizes Yield

Premium cutters include advanced nesting software that calculates the absolute optimal arrangement of required cuts on a given sheet of raw glass. This optimization drastically reduces the remnant waste. By pre-setting the necessary cuts via computer software, you eliminate the need for specialized molds required for irregular shapes, saving significant material and time.

Reduced Glass Breakage During Operation

A high-speed machine’s stability—built on a robust base frame mechanism and heavy-duty components—ensures that vibrations are minimized, even during rapid movement. This stability, combined with precise, computer-controlled cutting pressure, drastically lowers the risk of glass damage or breakage, leading to a higher successful yield.

Analyzing the True Total Cost of Ownership Versus the Initial Investment

The premium price is merely the Initial Price. True business insight requires you to look at the Total Cost of Ownership (TCO) over the machine's lifespan.

Lower Maintenance Needs Over Time

While the components in a high-speed machine are more complex, they are often built with superior quality materials and sealed systems designed for endurance. Components like the Yaskawa servo motors and advanced control cards are chosen for their reliability, leading to less frequent downtime and lower unexpected repair costs.

Significant Reduction In Raw Material Waste

This is where the premium investment quickly pays for itself. An improved material yield of just 1-2% across your annual production volume can translate into hundreds of thousands of dollars in material savings alone, far exceeding the initial cost difference.

Accelerated Depreciation and Tax Benefits

In many jurisdictions, industrial equipment qualifies for accelerated depreciation. A higher initial investment can therefore be managed favorably through accounting and tax planning, reducing the effective cost over the first few years of operation.

TCO Component | Standard CNC Cutter (Est. 5-Year) | High Speed CNC Cutter (Est. 5-Year) |

Initial Price | Low | High (The Premium) |

Waste Material Cost | High (Due to lower yield/rework) | Low (Optimized Nesting) |

Labor Cost | High (Needs more manual oversight) | Low (Fully Automated) |

Total Cost Over 5 Years | Often Higher Due to Ongoing Costs | Lower Due to Efficiency & Savings |

What Advanced Technologies Drive Wentrica's Speed and Reliability?

Wentrica designs and manufacture equipment for architectural glass, automotive glass, and mirror factories, ensuring that every machine, from simple handling systems to complex automated cutting lines, is built to meet high international standards.

The ability to achieve speed without sacrificing quality stems directly from the design philosophy and component sourcing.

Intelligent Control Systems For Optimized Performance

Wentrica’s Automatic Glass Loading And Cutting Integrated Machine and similar models utilize PC-based control systems. This allows for direct drawing and setup via computer software, eliminating the need for physical molds and allowing the machine to pre-set any shape—square, round, or irregular—with precision.

High Precision Yaskawa Servo Motors and Components

A reliable power and control system is paramount. Wentrica sources core components from well-known international brands, including high-precision servo motors and control mechanisms, ensuring smooth, high-velocity movement and precise mechanical positioning.

Robust Mechanical Design Ensures Longevity

The complex framework, consisting of the base frame, crossbeam, and cutter head mechanisms, is constructed for industrial resilience. This stable, sturdy framework is essential to manage the forces generated by high-speed operation, guaranteeing durability and consistent performance over the machine’s extensive operational life.

Which Wentrica High Speed Solution Matches Your Specific Factory Needs?

Wentrica offers solutions tailored to different automation levels and production requirements.

For Pure Cutting Focus The High-Speed CNC Glass Cutting Machine

If your factory already manages upstream handling well and needs to dramatically boost the efficiency of the cutting phase only, consider the High-Speed CNC Glass Cutting Machine with Intelligent Control System. This model provides the highest precision and smart system capabilities, designed to process complex orders quickly while maintaining material integrity.

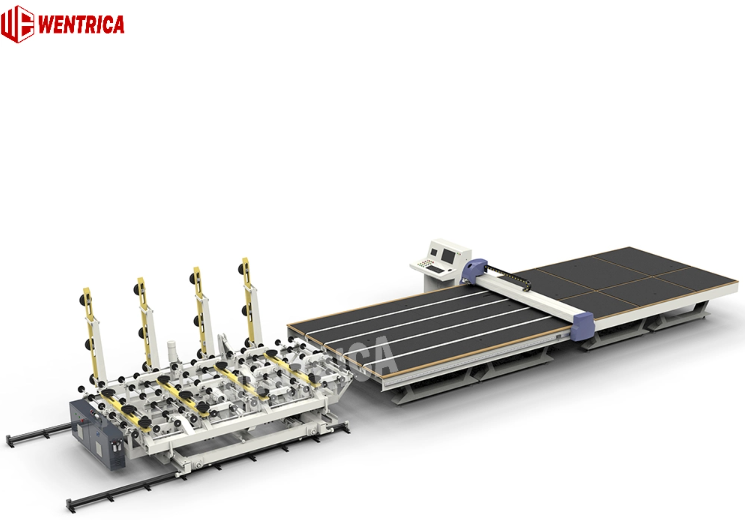

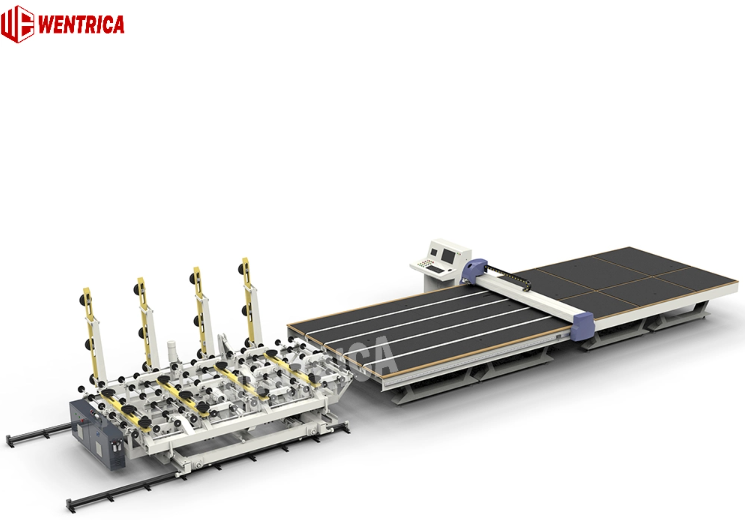

For Ultimate Automation The Integrated Machine Solution

If you are aiming for a full production line transformation, the Automatic Glass Loading And Cutting Integrated Machine offers an all-in-one efficiency from loading to cutting. This integrated approach minimizes transfers, reduces handling damage, and streamlines the entire workflow into one cohesive, automated process.

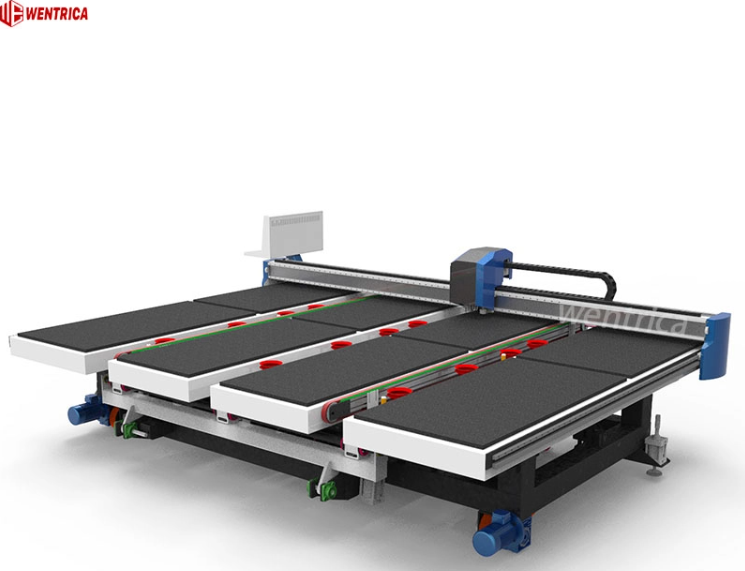

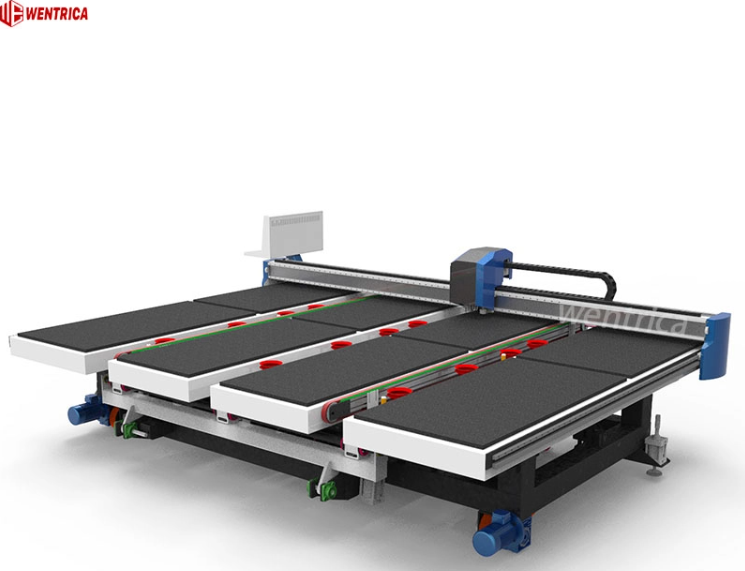

The CNC Full Automatic High Speed Glass Cutting Machine As a Proven Workhorse

For a reliable, established option that combines full automation with high speed, the CNC Full Automatic High Speed Glass Cutting Machine stands as a market-proven workhorse. Its design emphasizes high automation and continuous computer-controlled operation, making it ideal for large-volume, long-duration production tasks, with easy maintenance and servicing.

FAQ

Q1: Does a fully automatic cutting machine require special molds for complex shapes?

A: No. Fully automatic cutting machines are controlled by computer software. You simply draw the required shape on the computer, and the machine executes the cut, eliminating the need to create specialized molds for square, round, or irregular glass.

Q2: How do high-speed machines manage vibration at faster speeds?

A: High-speed performance is supported by a robust mechanical design, including the base frame mechanism and drive system. The construction minimizes vibrations, ensuring stability and accuracy even during rapid acceleration and high-velocity cutting.

Q3: Can these high-speed cutters integrate with existing factory equipment?

A: Yes. Modern CNC cutting machines are designed for seamless integration. They can be physically and digitally connected with other machines, such as loading tables and breaking machines, to establish a high-efficiency, fully automated production line.