Exact glass cutting plays a key role in today's factory and building work. From panels for tall buildings, to car windows, and to smart mirrors. The need for careful glass shaping keeps growing. But even with new tech, using a glass cutting machine in tough factory settings brings problems. These come from different glass types, high output needs, and changing designs.

Why Precision Glass Cutting Remains a Challenge in Complex Industrial Applications

In fields where each tiny bit matters, getting exact cuts in glass is not easy. The wide range of glass mixes and uses adds big issues to the cutting job.

Material diversity and thickness variations complicate cutting accuracy

Factory jobs often need cuts in many glass kinds—like joined, heat-treated, Low-E coated. Each has its own traits in weight, toughness, and heat response. Cutting works best when thickness stays even across the piece. But changes in thickness call for quick shifts in press force and pace. And most old tools can't keep up with that. Hand or half-auto machines find it hard to give steady results. This is true especially when moving to new glass types.

Limitations of traditional cutting methods in high-volume environments

Old hand or half-auto glass cutters depend a lot on worker know-how and set shapes. Manual glass cutters are the most traditional glass cutters. The whole machine has two main parts: a conveyor belt and a cutting table. They let you make some shape changes. But these setups slow down output and raise work costs. The downside is clear. To cut glass into set shapes, you need a special form. And with hand work, it's slow and needs many hands. So, big runs are not possible. Checking quality is another worry. Cut errors and uneven spots raise waste and fix-up costs. Plus, hand systems don't link well to auto flows or live checks.

Demand for intelligent automation across industrial sectors

Now's building styles and factory goods need shape exactness and sameness in big amounts. Gaps under one millimeter are normal for building panels or good heat glass units. Makers must meet short deadlines without losing quality. So, auto tools are a must. Smart setups with watchers and programs speed up steps. They also help spot issues ahead and improve work over time.

Intelligent CNC Cutting Technology for Industrial Glass Processing

To fix these issues, smart CNC tools bring big changes in exactness, quickness, and fit. They mix servo move control, live watching, and smart layout features for best results.

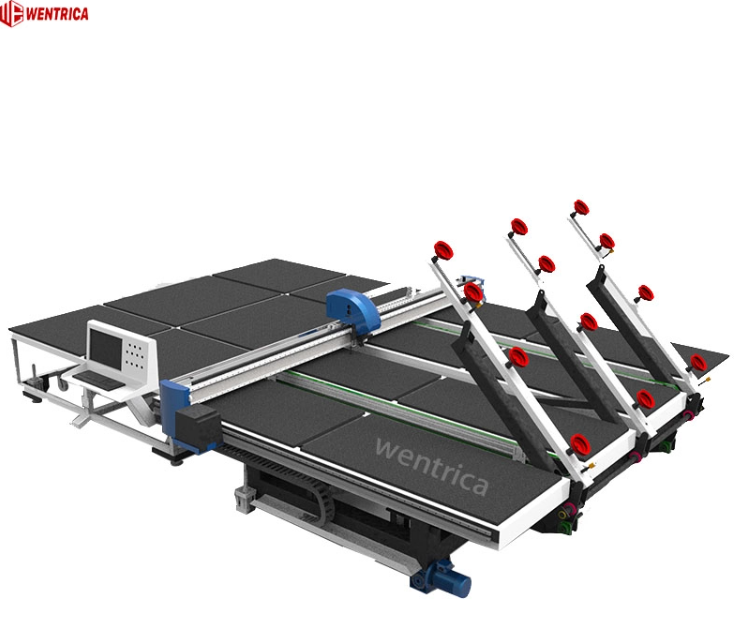

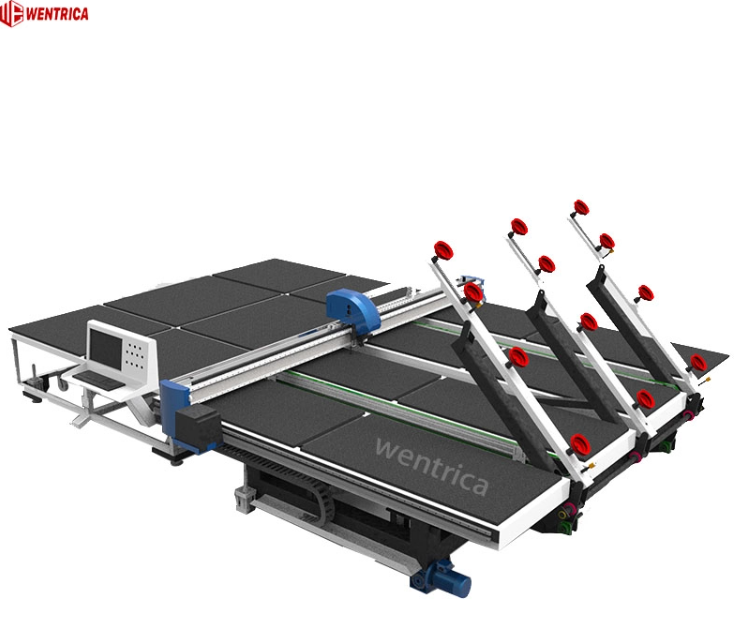

High-speed CNC systems enhance precision and productivity

Servo-led straight moves make the cut part go with full exactness over the work area. Check loops keep tweaking settings based on glass pushback or outside shifts. High-Speed CNC Glass Cutting Machines give turn freedom up to 360 degrees. This lets easy switches from straight paths to tricky bends. The cutting head of this glass cutting machine can rotate 360 degrees and supports various shapes of cutting. The setup's gear rack drive and laser spot keep a steady gap under 0.05 millimeters.

Automated nesting algorithms optimize material usage

Inner programs plan to cut down waste. They get the most from each glass piece. The layout step takes files right from CAD. This cuts start time a lot. It also boosts raw glass use. The goal is to fit as many cut parts as possible on the first glass sheet. That way, you save materials. Fix programs pick best setups based on run size, shape hardness, and glass limits.

Multi-axis control enables complex shape cutting with minimal error margins

Many-axis teamwork lets full auto shape changes without hand moves or special forms. If you deal with odd car glass or special pattern building sheets, top CNC types like the WE-4228 CNC Full Automatic High Speed Glass Cutting Machine give both quickness and rightness. They back auto run cycles too.

Integrated Loading and Cutting Systems for Workflow Optimization

In busy making spots, splitting load from cut steps makes waste. A joined way keeps flow in sync from raw input to done output.

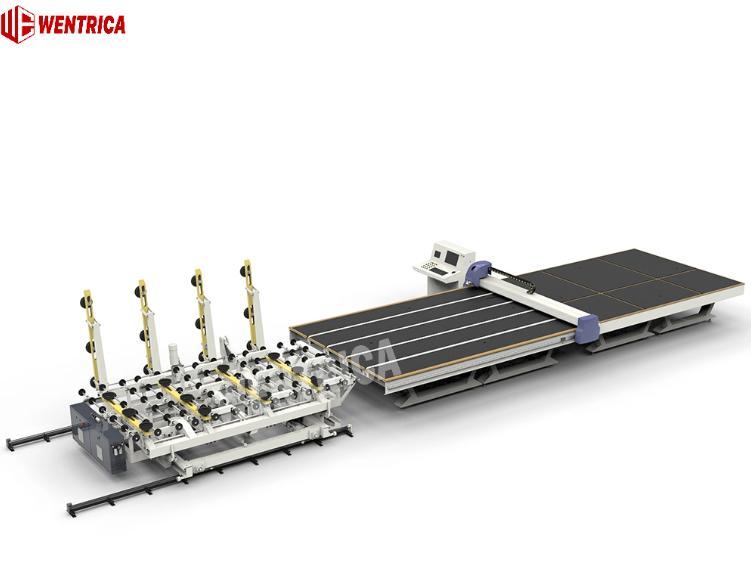

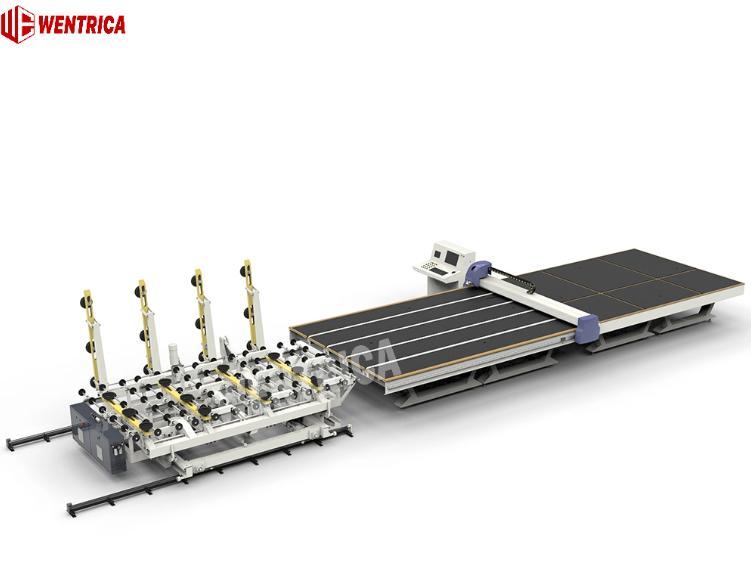

Automation of glass loading reduces handling time and labor risk

Auto load setups use suck arms or robot lifters to shift glass from hold racks to the cut table. This cuts break chances from people touch. This automatic glass loading and cutting machine is an advanced fully automatic solution specifically designed for handling large glass plates. The suck part smartly sets each sheet for true line-up before cuts start.

Synchronization between loading, cutting, and unloading improves throughput

A steady make cycle cuts wait time between steps. Tools like the Automatic Glass Loading And Cutting Integrated Machine have set PLC systems. They link every part—from plan pick to suck lift use. The result is smooth work over many shifts.

Compact system design saves factory floor space

Joined plans cut the need for split work spots. They mix many steps into one small space unit. This saves room and boosts safety. It does so by cutting worker walks between spots. Small floor area, save space(3900*3250*850mm).

Full Automation Capabilities for High-Demand Production Lines

Auto is not a choice anymore for top makers. It is key for exactness, growth, and steady work.

Real-time monitoring ensures consistent quality control across batches

Watchers in the setup keep track of things like cut push, heat changes, and tool wear. Off spots set off warnings for quick fixes before bad cuts happen. The whole cutting process is inspected to protect the cutting equipment in real time.

Remote control and data logging support Industry 4.0 integration

New tools link to far checks through net setups. Line bosses can watch work from away spots. Past data on work goes into guess fixes for upkeep. This cuts surprise stops and helps tools last longer.

Adaptive cutting parameters respond to specific requirements

Top programs spot traits of new glass—like thick or coat kind. They shift settings like blade push and cut deep on their own. Cutting pressure automatic adjusted according to glass thickness(SMC Pressure Sensor). This skips hand resets between tasks or glass kinds.

Why Choose Wentrica as Your Glass Cutting Technology Partner?

If exactness, growth, and joining are your main goals, Wentrica goes further than hoped. With over ten years helping clients worldwide in building glass work, Wentrica mixes build know-how with strong make setups. Their goods list has quick CNC bases, full joined auto systems, and custom fits for factory-scale jobs. Backed by quick tech help teams across lands, Wentrica keeps giving makers solid fixes that grow with your work needs.

FAQ

Q1: What types of glass can these machines process?

A: They support float glass, tempered glass, laminated glass, Low-E coated glass, and even insulating units.

Q2: How accurate are CNC-based glass cutting machines?

A: With laser positioning and servo-driven movement systems, typical tolerance levels are under 0.05 mm.

Q3: Do I need separate equipment for loading and unloading?

A: No. Integrated models combine loading, cutting, breaking, and unloading into one seamless operation.