Glass edge processing effectively turns raw, dangerous sharp edges into safe, beautifully polished finishes that prove vital for architectural projects, furniture production, and insulating glass manufacturing. This carefully structured multi-stage approach guarantees safety, visual appeal, and long-lasting strength while tackling common difficulties such as edge chipping, slow production rates, and uneven quality results.

Manufacturers frequently struggle with sharp edges that create serious safety hazards during handling and installation, or edges that simply do not meet strict requirements for tempered or Low-E glass applications. By carefully moving through well-defined stages of roughing, fine grinding, and fully automated finishing, you obtain superior outcomes that significantly boost product value and considerably cut down material waste.

When you look for dependable equipment to handle these essential processes, many professionals turn to Wentrica, a highly experienced glass deep-processing machinery manufacturer that consistently delivers creative and reliable solutions.

Why Are Sharp Glass Edges a Major Concern for Manufacturers?

Glass edge processing turns raw, sharp edges into safe, polished finishes. These finishes matter greatly for architectural work, furniture making, and insulating glass units. These edges put workers at real risk during daily handling, often cause unwanted chipping in later steps like tempering, and seriously affect proper sealing in insulating glass units. Inadequate cooling or unsuitable grinding heads only worsen these issues, frequently leading to cracks or substandard edge quality that drastically reduces overall yield rates. Tackling these problems right from the start helps avoid expensive corrections later and ensures full compliance with important safety regulations.

Rough Grinding Stage

Rough grinding acts as the crucial starting point: it rapidly removes excess material from newly cut edges to eliminate potential sharpness risks and prepare the surface for subsequent finishing. This initial phase emphasizes fast yet controlled material removal while always preventing heat-related damage or accidental breakage.

Importance of Initial Material Removal

Initial material removal quickly gets rid of hazardous sharp edges, thereby greatly lowering injury chances and allowing safe movement toward tempering or insulating production lines. Moreover, it establishes a solid and even foundation for all following stages by forming a consistent base edge that supports better final results.

Key Tools and Techniques in Rough Grinding

Dual-head setups work best and diamond or resin wheels cross for full contact. This smart design fully utilizes the wheel material, noticeably extends service life, and delivers much smoother starting edges when compared to older single-wheel approaches. Built-in water circulation systems supply necessary cooling, and easily adjustable speeds together with angle settings comfortably handle glass thicknesses ranging from 3mm to 12mm.

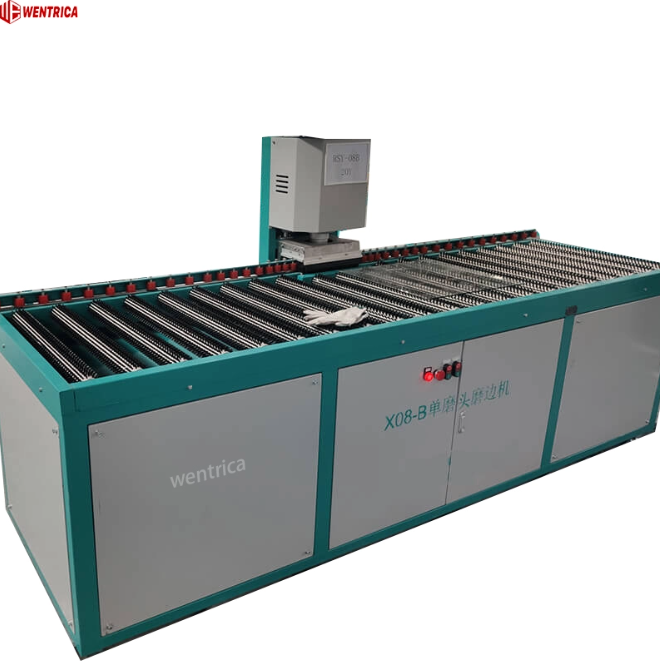

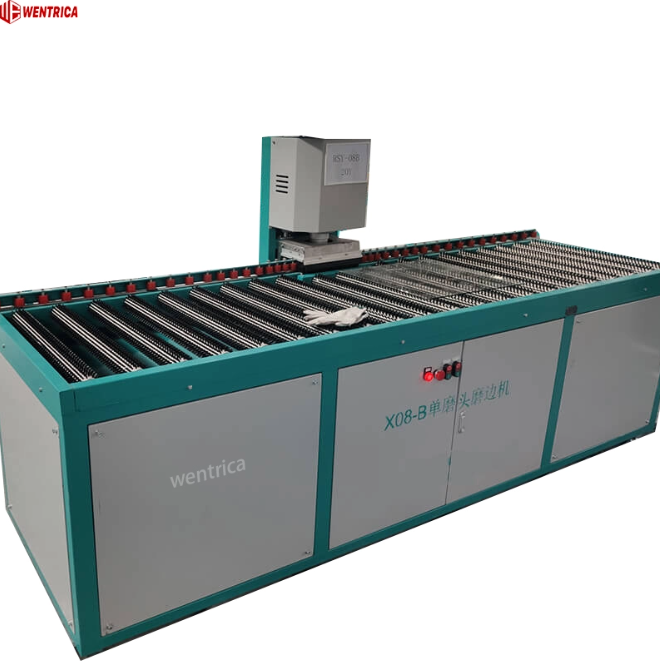

Wentrica's Solution for Efficient Roughing

For fast and highly effective rough grinding, the Industrial Rough Grinding Edging Machine includes a practical dual grinding head linkage that conveniently finishes roughing in just one smooth pass. Its flexible expandable platform easily manages sizes up to 2000x2000mm, and reliable temperature control effectively prevents cracking, which makes it a perfect choice for rapid flat edge preparation in busy workshops.

Fine Grinding Stage

Once roughing completes its job, fine grinding steps in to carefully refine the edge surface, achieving noticeably smoother texture and greater accuracy while gently erasing any scratches remaining from the earlier material removal. This important middle stage smoothly connects to final polishing and consistently delivers excellent optical clarity for applications where edges remain clearly visible.

Achieving Smoother Edges and Precision

Fine grinding skillfully uses several motors along with progressive wheels to steadily decrease surface roughness in a controlled manner. Advanced PLC systems provide exact management of pressure and speed settings, and this results in precisely shaped edges that work perfectly for beveling or straight-line finishing tasks.

Benefits of Multi-Motor Systems

Multi-motor arrangements, typically featuring 9 or even more heads, evenly share the workload to produce steady outcomes across large glass panels. They reliably support worm gear transmission that ensures smooth and continuous speed changes from 0-4 m/min, and this flexibility nicely meets varied processing demands without causing unwanted deformation.

Recommended Equipment for Fine Grinding

Modern machines often include sturdy cast iron bases for excellent stability and dependable Italian timing belts for secure clamping during operation. The Automatic Glass Edge Grinding Machine effectively employs 9 motors combined with intuitive PLC control. Through intelligent automated monitoring and precise adjustment, it can stably produce smooth and high-precision edges.

Full Automatic Finishing Stage

Full automatic finishing smartly combines polishing, chamfering, and multi-edge operations into efficient production lines, thereby dramatically improving throughput for large-scale manufacturing needs. Advanced automation greatly reduces the need for manual involvement and reliably maintains uniform final quality across every piece.

Seamless Polishing and Multi-Edge Processing

CNC systems accurately coordinate numerous heads to carry out roughing, fine grinding, polishing, and even film removal all at once. This efficient single-process approach fully supports four-edge grinding on rectangular sheets, and it proves especially valuable for architectural projects and insulating glass production.

Advantages of CNC Automation

CNC control featuring servo motors and user-friendly human-machine interfaces permits automatic positioning, variable speeds reaching up to 30 m/min, and remarkably low error rates under 0.05mm. Integrated diagnostics plus water-saving features further improve operational safety and promote sustainable practices in the workshop.

High-Efficiency Four-Edge Solutions

Horizontal four-edge machines comfortably process large formats such as 2440x3660mm using 24 grinding heads that include diamond, resin, and polishing wheels for complete coverage. The Automatic CNC Horizontal Type Glass Four Edges Grinding Machine provides CE-certified accuracy and dependable performance for demanding industrial-scale operations.

Why Choose Wentrica for Your Glass Edging Needs?

Picking the most suitable supplier ensures you gain access to robust, forward-thinking equipment supported by deep knowledge in glass deep processing. Trustworthy manufacturers supply corrosion-resistant frames, high-quality imported parts for extended durability, and integrated solutions that smoothly cover roughing through to finishing stages.

Prioritize partners with strong proven histories in delivering efficiency, precision, and responsive customer assistance to minimize equipment downtime and substantially increase production yields over time.

FAQ

Q1: What is the main purpose of rough grinding in glass edge processing?

A: Rough grinding swiftly removes sharp edges right after cutting, significantly reduces safety risks, and properly prepares the glass for tempering or additional refinement steps.

Q2: How does fine grinding differ from rough grinding?

A: Fine grinding carefully applies multiple motors and progressive wheels to smooth out scratches left by roughing, thereby achieving much higher precision and superior surface quality overall.

Q3: Why is automation important in the finishing stage?

A: Automation skillfully synchronizes various processes such as polishing and chamfering, greatly boosts processing speed, minimizes potential errors, and reliably supports consistent high-volume production.

Q4: Can one machine handle multiple edge processing stages?

A: Yes, sophisticated machines equipped with dual heads or advanced CNC systems efficiently complete roughing, fine grinding, and polishing either in single operations or through well-connected lines.