Glass straight edge machines handle the tough job of grinding flat edges on sheets, turning rough cuts into smooth, safe finishes ready for tempering or insulating glass lines. You deal with daily headaches like chipped edges, slow throughput, or machines that break down mid-shift. These tools fix that. Picture this: a busy shop in Tianjin runs batches of furniture glass without stopping for repairs. As an expert who has walked factory floors from Guangdong to Shandong, you know reliable gear matters. Check out Wentrica, a manufacturer that builds everything in-house at their modern factory with a team focused on glass processing solutions.

Why Choose a Glass Straight Edge Machine?

You pick tools that match your shop's rhythm. Straight edge machines shine when precision meets speed in everyday runs.

Spot-On Accuracy

Edges come out exact every time. The machine uses cast iron guide rails and motor bases, aged naturally for flatness. No warping after years of heat and water. You grind glass from 3mm to 25mm thick, hitting sizes up to 2440mm by 3000mm with extension tables. Mini pieces down to 40mm by 40mm work too. Chamfer at 45 degrees without fuss. In a real setup, one factory cut door panels and saw zero rejects from edge flaws.

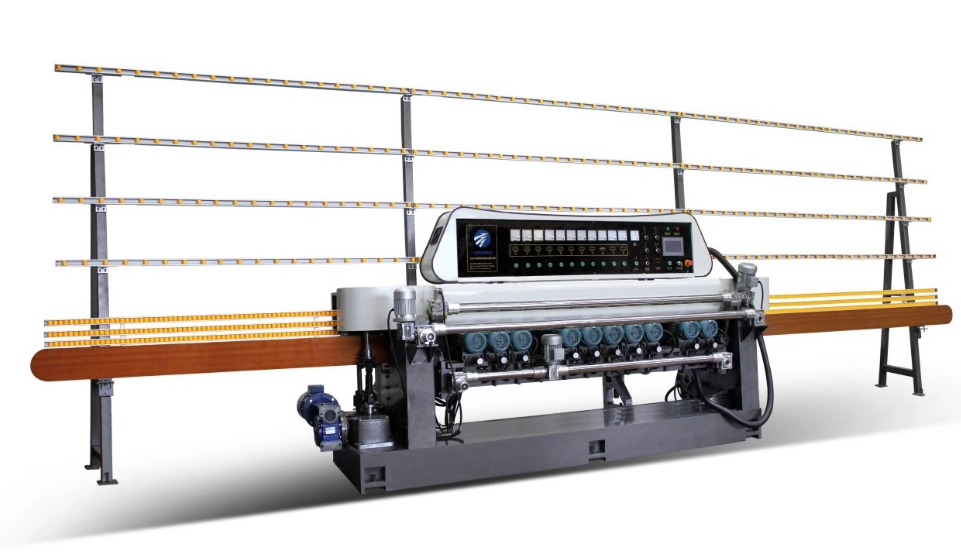

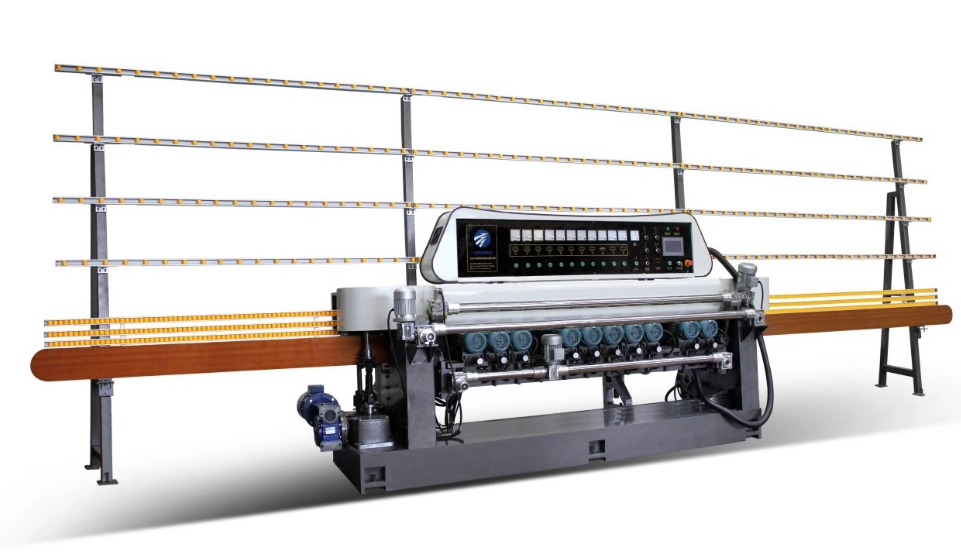

Faster Work

Speed adjusts from 0 to 4 meters per minute. Worm gear transmission keeps it steady, no jumps. You process more sheets per hour than manual methods. A line with seven motors finishes a straight edge in one pass. Add it before tempering, and the whole floor moves quicker.

Works for Many Jobs

Straight edges for home glass, furniture, or building frames. It handles granite or tile too. You switch jobs without new setups. One machine grinds bottom edges and corners, preps for insulating units. Shops use it daily for craft pieces or large slabs.

These points tie into your need for reliable output. Accuracy cuts waste, speed boosts volume, versatility fits varied orders. Next, see how quality jumps.

How Does a Straight Edge Machine Boost Product Quality?

Quality shows in the final piece. Smooth edges mean safer handling and better fits.

Polished Edges

Grinding wheels include diamond for rough, resin for fine, BD for polish. You get glossy finishes that pass inspection. Edges stay clean, no burrs. Factories report higher tempering yields because pre-grind removes weak spots.

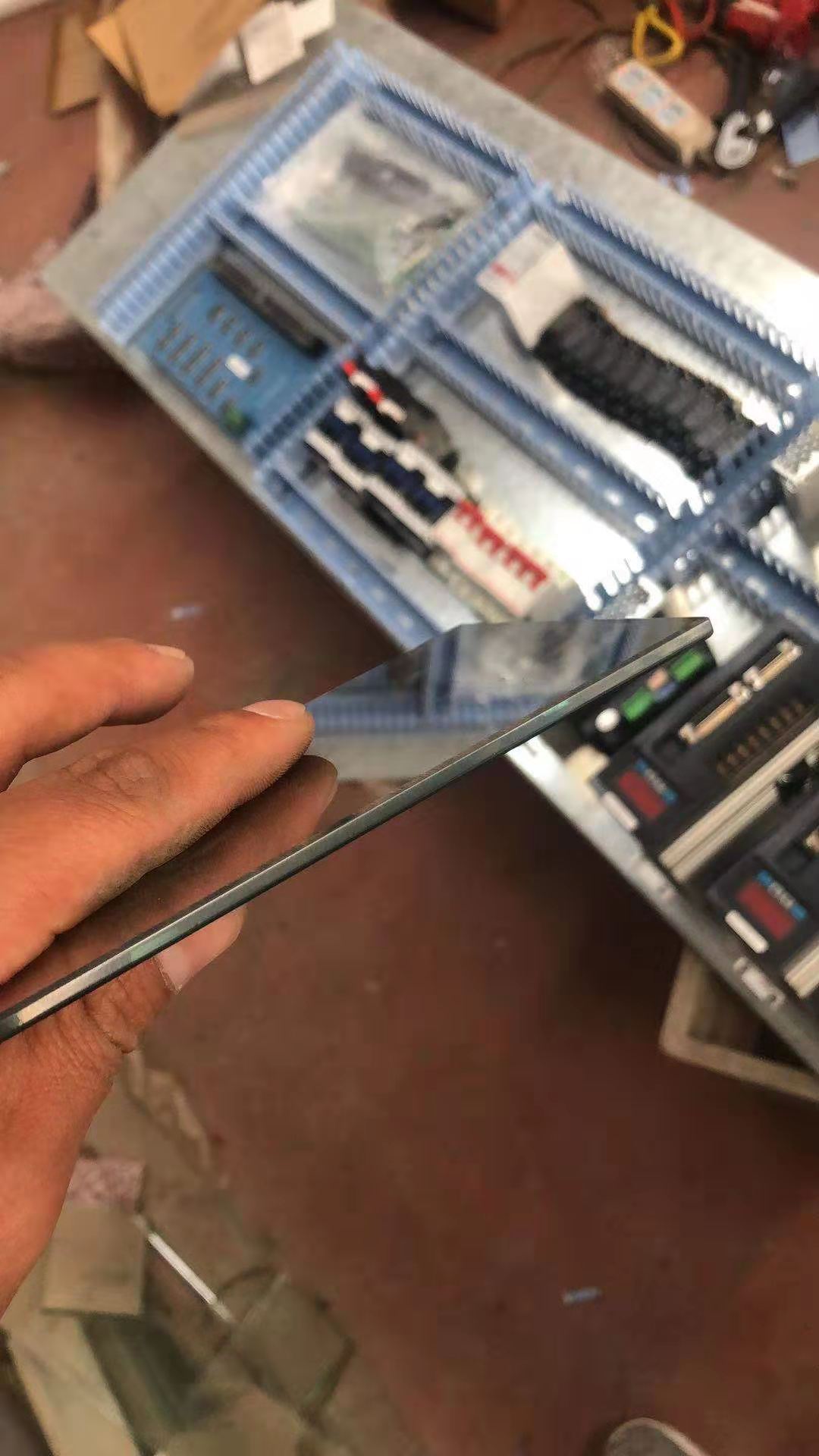

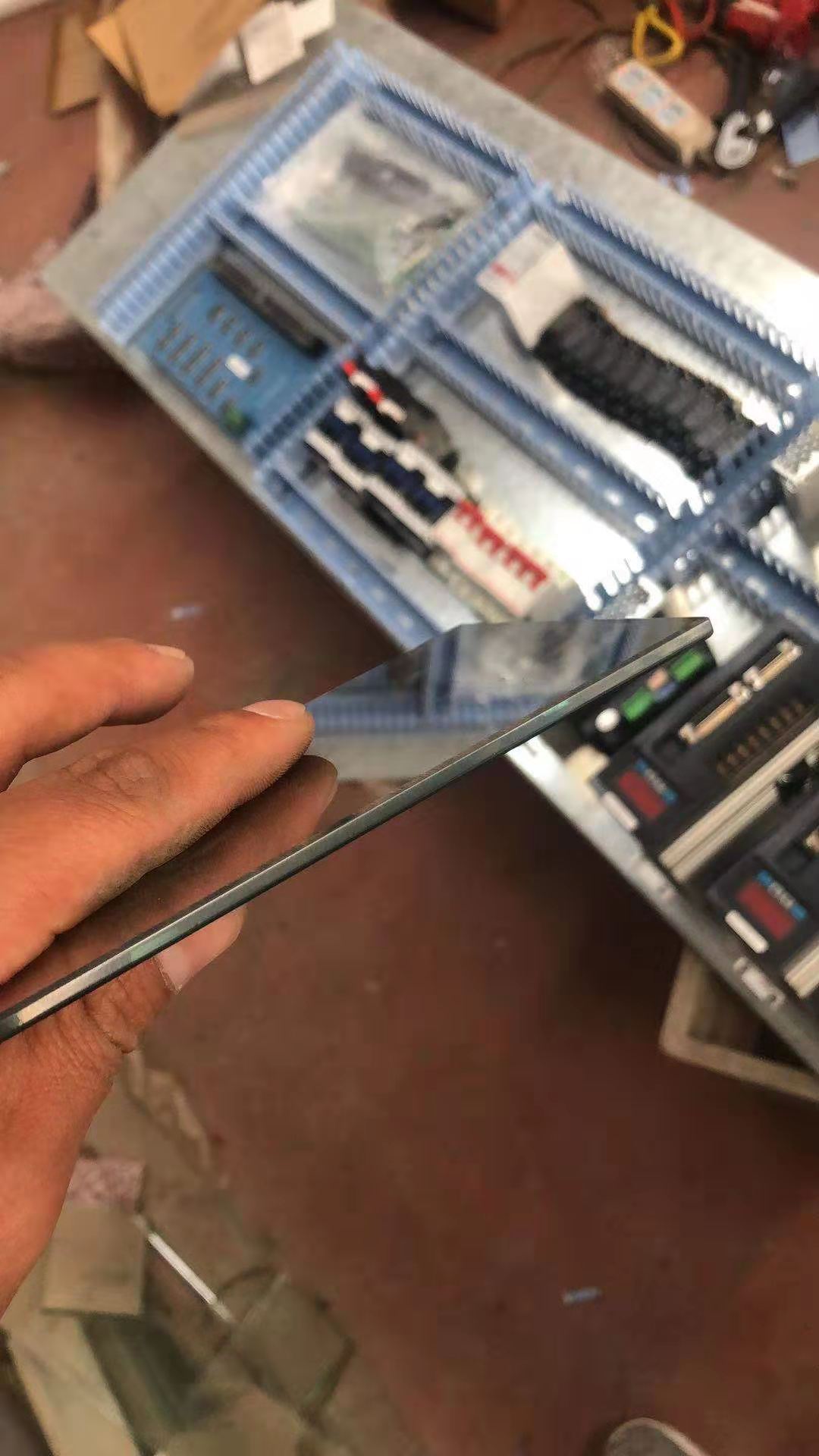

Less Wasted Glass

Clamping uses Italian timing belts with PU surface. Grip is firm but gentle, no cracks on thin glass. You test by hand-pulling a stopped machine; it holds tight. Waste drops since breaks happen less.

Built to Last

Motors last 20 years, wheels grind 3000 meters. Cast iron body, no welds. You run shifts without part swaps. One shop tracked a machine over a decade with minimal downtime.

Quality ties back to choice. Precise machines produce better glass, durable builds keep standards high. Now, what sets top models apart.

What Makes These Glass Edging Machines Special?

Standout features come from smart design. You get tech that simplifies tough tasks.

High-Tech Features

Three-phase motors run quiet. Circulating water cools without external hooks. You place it anywhere with power. Digital displays show current and voltage. Speed changes mid-run via frequency control.

Options to Customize

Add film removal wheels for coated glass. Extend tables for bigger sheets. You pick motor counts, seven or eight for your needs. Custom setups match automatic lines.

Great Support

Contact Wentrica for guides and quick fixes. Downtime stays low, so your shop keeps humming. Features build on quality gains. Tech eases operation, customs fit your line, support minimizes stops. Durability matters most in wet environments.

Why Is Durability a Big Deal for Glass Edging Machines?

Glass work splashes water and grit. Machines must withstand that daily.

Long-Lasting Performance

Bearings seal against water, filled with grease. You grind without rust eating parts. Electrostatic spray coats the frame, shines after years.

Rust-Proof Design

No cheap paint that flakes. Full coating fights corrosion from grinding water. You clean easy, no hidden rust spots.

Handles Heavy Loads

Body integrates steel plate and cast rails. Power hits 13kW or 14.5kW. You process thick sheets non-stop. Net weight around 2000kg keeps it stable.

Durability supports everything. Tough machines deliver accuracy and speed shift after shift. Safety comes next in busy shops.

How Do These Machines Keep Your Team Safe?

Edges grind fast, water flies. Safety builds into every step.

Safety Systems

Springs buffer contact, no sudden breaks. You adjust pressure with hand wheels, avoid overload. Vacuum holds if power dips in related tools.

Firm Grip

Belts clamp without slipping. You set force to match glass thickness. Thin sheets stay put, no drops.

Easy Controls

Buttons and valves sit clear. You train new hands quick. Observation windows let you watch without opening.

Safety links to durability. Solid builds prevent failures that hurt. Cost savings follow from efficient runs.

How Can You Fit These Machines into Your Setup?

Integration turns good tools into profit makers. You slot them seamless.

Fits with Other Equipment

Height matches washers. You link direct, grind then clean without offload. Place front or side.

Simple Setup

Plug in, fill water tank. No external source needed. You move with wheels if needed.

Grows with You

Add motors later. Handle small crafts to big panels. You scale as orders grow.

For a solid example, take the WEX371P model. Eleven motors polish flat or laminated glass fast. It fits the durability and safety talk, with custom options.

FAQ

Q1: What glass thicknesses does it handle?

A: From 3mm to 25mm thick, covering thin crafts like frames to thick doors and panels.

Q2: How long do grinding wheels last?

A: Resin wheels last over a month, diamond wheels about six months with eight-hour daily use.

Q3: Can it remove film too?

A: Yes, the side wheel removes coated film in one pass; lift the motor when not needed.

Q4: Is water hookup required?

A: No, it has built-in water circulation; connect power and refill the tank occasionally.

Q5: How do you adjust edge amount?

A: Turn the front hand wheels to slide motors forward or back, simple and precise control.