Investing in high-end industrial gear is just the initial step toward building a lasting glass processing venture. If you want your production line to stay profitable for many years, you need a solid maintenance plan. For those looking for top-tier gear, Wentrica is a maker that focuses on premium glass machinery. They run a modern factory where precision engineering is the main goal. They build equipment meant for tough, daily industrial work. Their company profile highlights deep skill in both vertical and horizontal washing tech. This makes them a reliable partner for glass shops worldwide.

Why Is Your Glass Washing Machine Failing to Deliver Spotless Results

Mechanical breakdowns and poor cleaning often happen because of tiny details that people overlook. These small issues grow over time. When a glass washer stops working well, it causes immediate financial pain. You deal with rejected glass and wasted hours of labor. To fix these headaches, you must spot the common triggers that lead to wear and surface flaws.

High cost of unexpected equipment downtime

Sudden breakdowns stop the whole line. This leads to late deliveries and high repair bills. If you do not have a preventative schedule, a tiny bearing problem can turn into a total disaster. It can freeze your entire output for days.

Common causes of glass surface scratches

Scratches often happen because glass powder gets stuck in the brush bristles. If you do not clean the washing chamber, these tiny shards act like sandpaper. They rub against the glass surface while the brushes spin at high speeds.

Hidden impact of poor maintenance on energy

Dirty filters and dry transmission parts make motors work much harder. This pushes your power bills higher than they should be. Over time, this extra stress wears out the motor. It raises the total cost of running your shop.

Tip 1: Daily Inspection and Cleaning Protocols

Daily habits are the core of a long machine life and steady quality. Spend a bit of time at the end of every shift to tidy up key parts. This stops glass mud and lime scale from building up. These nasty substances can ruin sensitive components forever.

Cleaning water tank debris daily

You must clear out glass fines and sludge from the water tank every single day. Do not let them sit there. If you leave them, they go back into the pipes. They can clog the spray nozzles. This leads to dry spots on the glass and a bad clean.

Rinsing nylon brush rollers regularly

Give the brushes a good rinse after every shift. This keeps the bristles soft and clean. High-quality nylon is tough, but it still needs a wash. You want to stop hard grit from scratching the next piece of glass that goes through.

Checking air knife drying efficiency

The air knife has to be totally clear to work right. It needs to strip all water off before the glass leaves. Check the air intake filters daily. You do not want dust blowing onto your freshly washed glass at the very last second.

Tip 2: Water Quality and Filtration Management

The water you use is just as vital as the machine itself. If the water is hard or dirty, it leaves ugly spots and streaks. It does not matter how good your brushes are if the water is bad. A strong filtration setup protects the glass and the machine parts from rust.

Monitoring water conductivity levels regularly

Test your water conductivity often. This is huge when you handle Low-E or coated glass. High mineral levels can mess with the glass coating. Using deionized water for the final rinse is the best way to get a perfect finish.

Replacing primary filter elements timely

Primary filters keep the high-pressure pumps safe from tiny rocks and glass bits. Replace these filters on a strict timetable. Do not wait for the water pressure to drop. By the time that happens, your pumps might already be struggling.

Monitoring pH balance of circulating water

Keep the pH level neutral. This stops the metal frames and rubber seals inside from rotting away. If the water gets too acidic or becomes too alkaline, it can eat into the glass surface. It also damages the machine's inner structure.

Tip 3: Monthly Mechanical Alignment and Lubrication

Moving parts need grease and perfect alignment to stay healthy. Friction is the enemy here. Over a month of work, the vibration of the conveyor can cause parts to shift slightly. Small tweaks keep everything running like a clock.

Lubricating transmission chains and bearings

Apply water-resistant grease to every chain and bearing. Do not skip any. Standard grease is useless in a wet environment because it just washes away. Without the right grease, metal parts will rust and seize up fast.

Adjusting rubber rollers working pressure

You must set the roller pressure to match the glass thickness. If the grip is too tight, you might crack thin sheets. If it is too loose, the glass will slip. This causes friction burns that ruin the piece.

Calibrating conveyor belt running tension

A floppy conveyor belt leads to uneven speeds and annoying jams. Check the tension every month. You want the drive motor to run easy. This ensures the glass glides through the drying zone without any hiccups.

Tip 4: Long-Term System Optimization and Parts Replacement

Beyond the daily and monthly chores, long-term health needs a deep check-up. Be proactive about swapping out old parts. If you wait for something to snap, it usually breaks the parts next to it too. That makes the fix much more expensive.

Descaling the entire circulation system

Lime scale builds up inside the pipes and nozzles over time. This chokes the water flow and kills efficiency. Use a professional descaler once in a while. Run it through the whole circuit to clear out those hidden mineral rocks.

Replacing worn brush rollers strategically

Brush bristles eventually lose their spring and cleaning power. Watch the brush height closely. Swap the rollers out before they get too short. If they cannot reach the tiny pores of the glass, your cleaning quality will tank.

Inspecting electrical control cabinet safety

Dust and loose wires in the electric box are dangerous. They can cause shorts or even fires. Clean the cabinet and tighten the terminal blocks once a year. This keeps the sensitive electronic brains of the machine safe and steady.

Why Choose Wentrica for Your Glass Processing Production

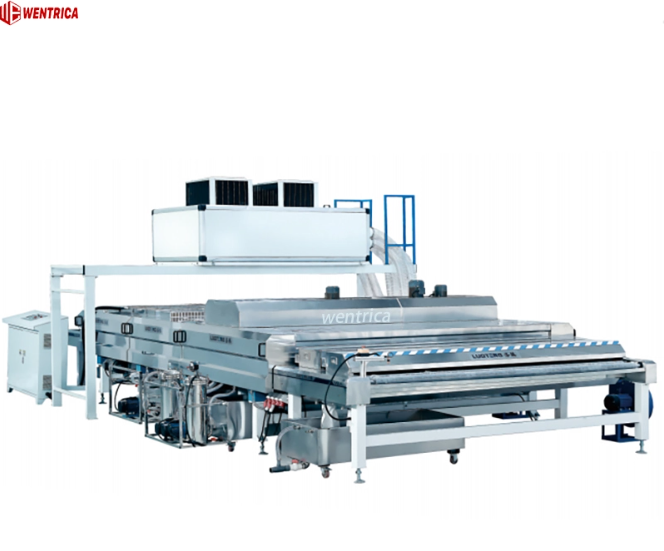

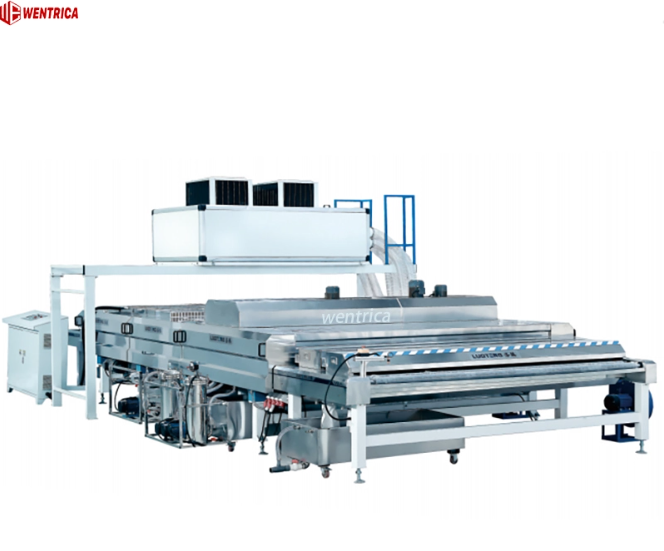

Picking a machine that is easy to fix makes your life a lot simpler. The High-Efficiency Horizontal Glass Washing Machine is built with great materials. It uses tough nylon brushes and stainless steel. These parts handle the wet, harsh world of a glass shop with ease.

Durable design of Wentrica Horizontal Washing Machine

The frame is very sturdy and has a special coating to stop rust. This smart design cuts down on structural wear over the years. It helps you keep your repair budget low. It also ensures the machine has a very long life in your factory.

Professional manufacturing standards at Wentrica factory

Every unit goes through tough tests before it ships out. The team checks the alignment and balance carefully. This precision work means less vibration when the machine is running. It protects the mechanical parts and makes your maintenance job much lighter.

Reliable technical support from Wentrica team

Even if you have your own mechanics, help from the maker is a huge plus. Their technical tips help you solve tricky problems fast. They make sure your gear stays at peak performance for many years to come.

FAQ

Q1: How often should the water in the glass washing machine be changed?

A: You should change it every day. If you are running a lot of glass, change it every shift. This stops glass dust from building up and scratching your products.

Q2: What type of water is best for achieving a streak-free finish?

A: Deionized or distilled water is the top choice for the last rinse. It gets rid of mineral spots. It makes sure the glass is totally ready for coating or laminating.

Q3: How can I tell when the brush rollers need to be replaced?

A: Check the bristles. If they look flat, feel soft, or fail to clean off light dirt even after you adjust the pressure, it is time for a new set.