Every year, more than 3000 serious glass installation accidents still occur worldwide. A single dropped jumbo panel (3660×2440 mm) can shatter into thousands of razor-sharp pieces, injure workers, and cost over $180,000 in medical bills, replacement glass, and delays. You already train your teams and follow regulations, yet the risk remains because most accidents happen when generic slings, fixed bars, or under-rated vacuum cups meet real-world glass weights and heights. The only reliable fix is purpose-built handling equipment that eliminates the weak points you face every day. Wentrica has manufactured exactly these solutions in its factory, shipping to more than 60 countries with full OEM/ODM capability.

Why Do Glass Installation Accidents Still Happen in 2025?

Jumbo glass keeps growing while many teams still use yesterday’s tools. Fixed-length slings slip on 3300 mm or 3660 mm panels. Vacuum cups without power-off protection drop glass the moment air pressure fails. Poorly balanced loads create edge pressure that later explodes in the tempering furnace. Even perfect edge grinding cannot save glass that arrives with hidden stress from bad transport. These failures are not bad luck; they are the direct result of equipment that was never designed for today’s panel sizes and site conditions.

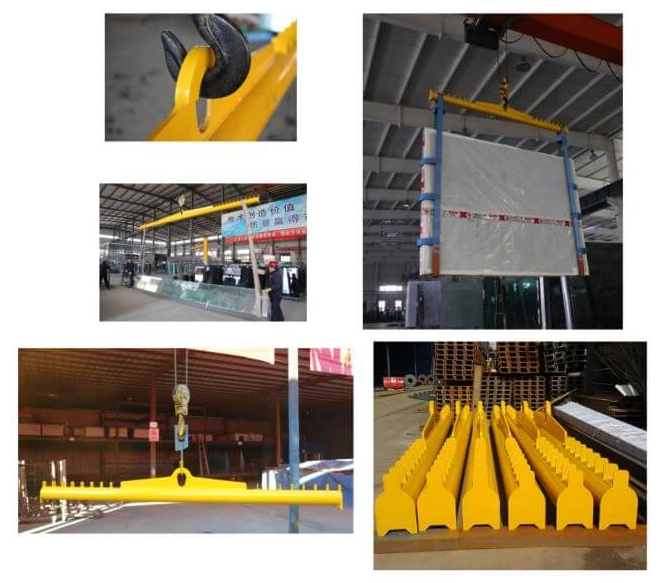

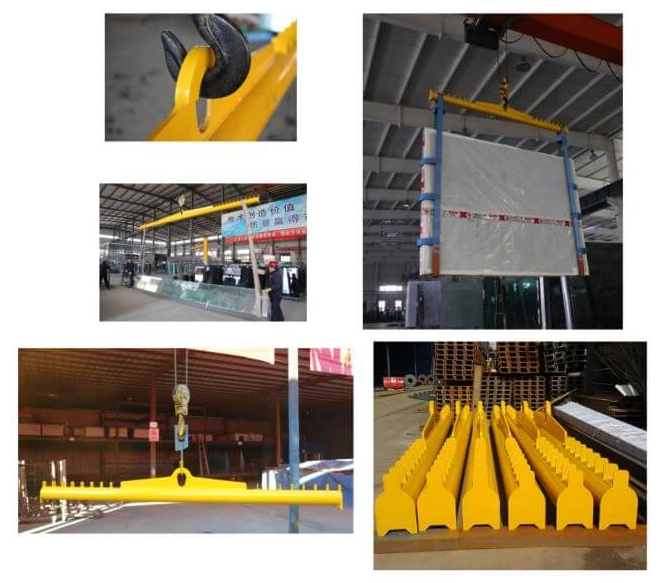

Overhead & Curtain Wall Lifting – Zero-Drop Solutions

When you lift glass 20, 30, or 50 meters high for curtain walls or overhead glazing, balance and grip decide everything. The right lifting bar adapts instantly to any length from 2000 mm to 3660 mm, spreads the load evenly across seamless 146 mm steel pipe, and locks the panel with rubber-coated hooks that never scratch or slip.

8-position quick-adjust lifting bar (2000-3660 mm universal)

Eight marked positions let you change length in seconds without tools. This removes the dangerous practice of adding chain extensions or using the wrong bar for the job.

146 mm seamless pipe + 4-ton safe working load

The oversized seamless steel pipe distributes force perfectly, while industrial-grade welding and 4-ton rating give you a safety margin even with the heaviest Low-E or triple-silver coated units.

Rubber-coated hooks + lifetime anti-rust epoxy finish

Rubber coating prevents edge damage and slippage on hollow glass. The epoxy paint survives years of outdoor storage without rust, so the bar stays reliable season after season. Explore the exact tool trusted on projects from Tianjin to Dubai: Adjustable Glass Lifting Bar.

Container Unloading – One-Man, Zero-Injury Operation

Unloading a 40-foot container used to require four people inside the box, exposed to falling packs and crush risks. Today, one operator stays safely on the forklift while a dedicated loading arm reaches 6000 mm deep, lifts 2700 kg packs, and places them exactly where you need them, without any forklift modification.

Heavy-duty U-shape loading arm (6000 mm reach)

The long U-shape arm slides straight into the container and grabs the pack from the top, so you never need to climb inside or stand under suspended loads.

2700 kg capacity, no forklift modification required

It handles full container packs of float, tempered, or laminated glass. The simple fork-pocket mount means you install it in minutes and start working immediately.

Maintenance-free design with instant container entry

Grease-free bearings and hot-dip galvanizing keep it working for years with zero daily upkeep. Teams regularly cut unloading time from hours to under 30 minutes. See how teams cut unloading time by 75 %: Heavy Duty U Shape Container Loading Arm.

High-Reach Projects – Forklift-to-Crane in 5 Minutes

Some installations demand crane reach but happen where cranes cannot go. Convert any forklift into a fully rotating mini crane in under five minutes. Telescopic extension, 360° rotation, and built-in load indicators give you precise placement at height without renting expensive equipment.

Telescopic forklift crane arm with 360° rotation

Extend or retract while the load is in the air and rotate a full circle, so you position oversized panels exactly where the architect drew them, even around corners.

Universal quick-mount system fits all forklifts

Slide-on fork pockets and safety pins lock it to any standard forklift in minutes. No welding, no drilling, no downtime waiting for a mobile crane.

Built-in load indicator + CE-certified safety hooks

Real-time weight display prevents overload before it happens. The certified hooks and safety latches meet European and global lifting standards, keeping your insurance company happy. Discover the tool that replaces rental cranes on hundreds of sites: Forklift Crane Arm.

Why Global Installers Trust Only Wentrica

You need more than a supplier; you need a partner that removes risk before it reaches your site. Factory-direct pricing eliminates middlemen markups. Full OEM/ODM service builds exactly what your projects demand. Every product leaves a destructive-testing lab with CE, SGS, and ISO9001 certification, plus lifetime technical support. Teams in Tianjin Yaopi, Dubai Marina towers, and European jumbo-glass processors made the switch and never looked back.

10+year factory-direct pricing (no middlemen)

You buy straight from the production line, so you pay 20-40 % less than through trading companies while getting higher quality control.

Full OEM/ODM + in-house destructive testing lab

Change length, capacity, or color to match your exact glass sizes. Every new design is broken on purpose in the lab before it ever reaches your site.

CE/SGS/ISO9001 + lifetime after-sales support

Certificates are real and current. Spare parts ship the same day, and engineers answer questions for the entire life of the tool.

The right handling tools do not cost money; they make money by preventing accidents and speeding installation. Upgrade once and protect your people, your profits, and your reputation for years.

FAQ

Q1: Can one lifting bar really cover glass from 2000 mm to 3660 mm safely?

A: Yes. Eight quick-adjust positions on a 146 mm seamless steel pipe with 4-ton rating handle every common length without load shift.

Q2: How long does container unloading take with the U-shape arm?

A: One operator typically empties a 40-foot container in 20-30 minutes instead of 2-3 hours with manual teams.

Q3: Do forklift crane arms require forklift modification or certification?

A: No modification needed. Universal mount and CE certification let you use them immediately on any standard forklift.

Q4: What happens if glass length changes mid-project?

A: Adjustable bars and custom OEM options mean you never face downtime waiting for new tools.

Q5: How do these tools reduce insurance premiums?

A: Documented use of certified, purpose-built equipment regularly cuts premiums by 15-30 % because claims drop to near zero.