A single flaw can scrap thousands in material and hours of labor. In glass processing, the washing step sits right before insulating units, coating lines, or tempering furnaces. Get it wrong, and everything downstream suffers.

A reliable processor needs proven gear. Enter Wentrica, a 15-year veteran in glass handling gear with three factories spanning over 6,000 square meters total. ISO 9001 and CE certified, they ship to more than 50 countries from Wentrica.

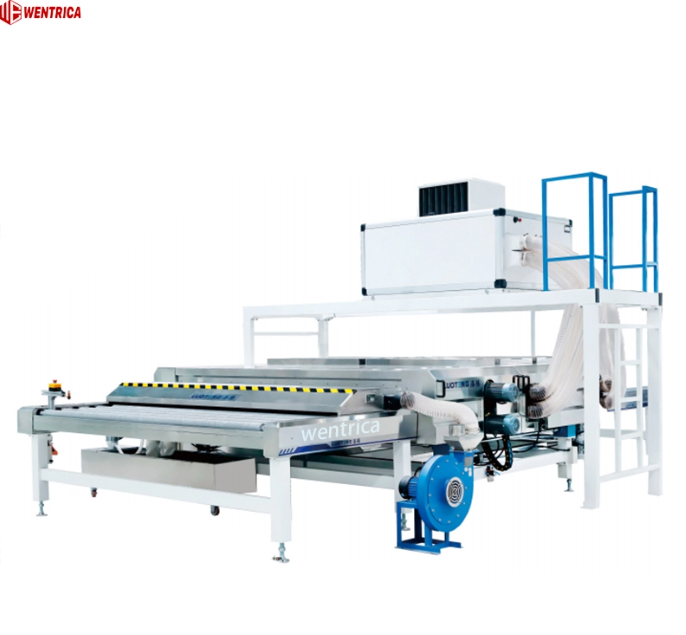

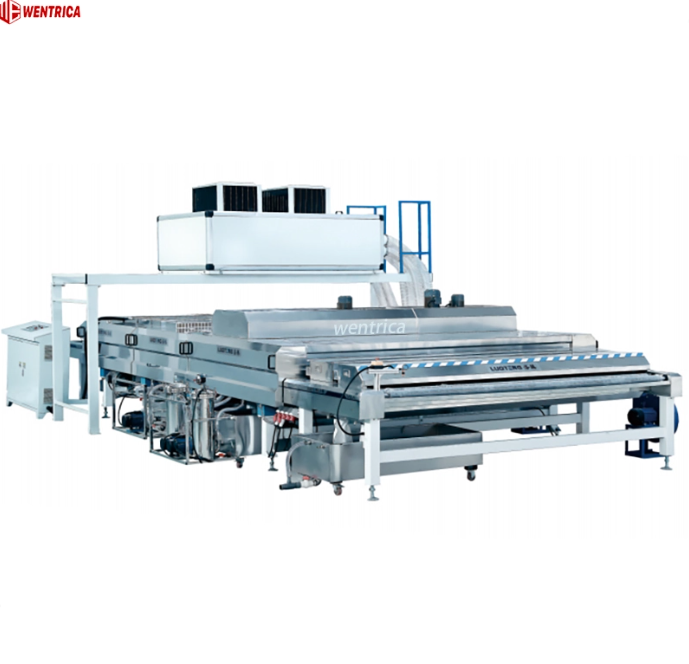

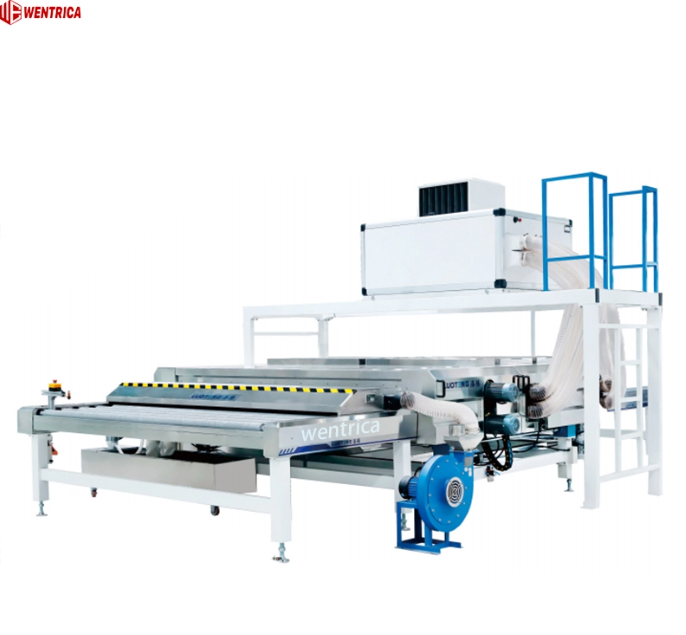

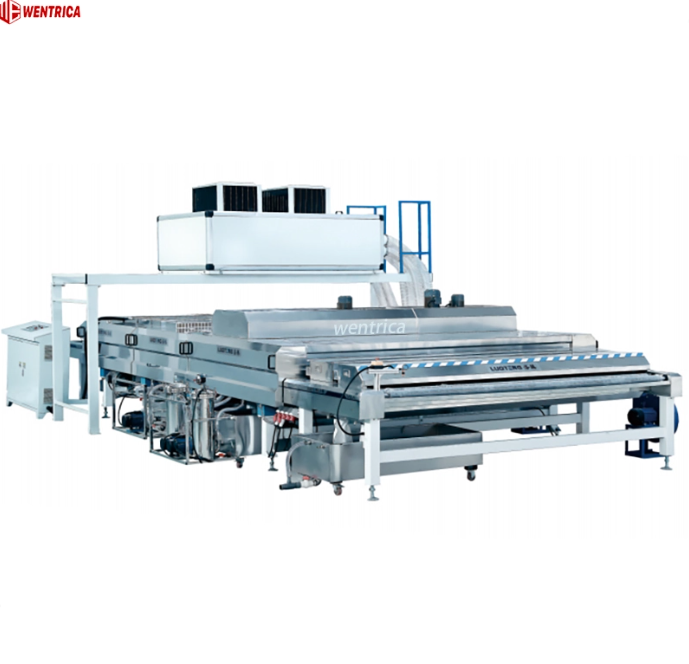

The Horizontal Type Glass Washing Machine is a specialized equipment used in the glass processing industry to clean, wash, and dry flat glass sheets before subsequent processes such as tempering, laminating, coating, or insulating.

What Processing Capacity Do You Really Need?

Capacity questions hit first because mismatched machines waste space or leave you short on output. Start with the biggest sheet you cut today and the thickest pack you plan tomorrow. A line built for 1600 mm widths chokes on 2440×3660 mm jumbos. Thickness matters too; 3 mm smartphone cover glass bends differently than 25 mm architectural slabs. Factor in shift length. Eight hours at 800 pieces beats four hours at 600 when orders pile up.

Maximum Glass Size and Thickness Range

Jumbos up to 2440×3660 mm run daily in insulating glass plants. The featured horizontal washer handles exactly that, plus 3–25 mm thickness without gear swaps. No awkward extensions needed.

Pieces per Hour vs. Shift Reality

Speed claims look great on paper, but real lines slow for Low-E pre-rinse. This model delivers 800–1200 pieces in an eight-hour shift at 10 m/min, leaving buffer for coating-sensitive glass.

Single-Line or Integrated IG/Tempering Compatibility

Standalone washers work, yet linking to automatic sealing robots or tempering loaders cuts handling. The machine’s 2–5 mm height offset matches upstream loaders and downstream breakers perfectly.

How Critical Is Coating Protection for Your Products?

Low-E coatings scratch easier than plain float. One metal roller touch and the film clouds, forcing scrap. Tianjin factories report 0.8 % lower reject rates after switching to soft brushes and deionized water loops. Protect the film, protect the margin.

Soft-Brush + DI Water System

Nylon PA1010 or PA612 filaments at 0.12 mm diameter scrub gently. Four-stage DI water keeps conductivity below 15 μS/cm, the threshold where ions etch silver layers.

Zero-Metal Contact Zones

Rubber-coated dovetail staples and built-in steel plates in racks prevent edge nicks. The washer’s entry zone uses the same rubber pads listed across A-frame and double-L specs.

Low-E Dedicated Pre-Wash Section

A separate pre-rinse tank floats dust before main brushes spin. Plants running 70 % Low-E glass add this section and watch pinhole defects drop.

What Drying Performance Prevents Water Marks?

Water spots appear the moment glass exits the final rinse. Hot air must hit every corner before rollers touch again. Tilted knives and recirculation cut energy while clearing droplets.

High-Volume Tilted Air Knives

Four 45 kW blowers angled at 75° blast 99.5 % dryness at 10 m/min. Compare that to upright knives that leave streaks on the bottom edge.

Hot-Air Recirculation Efficiency

Closed-loop heaters reuse 70 % of the air, trimming power draw by 30 % against open-vent competitors. Eight-hour shifts save roughly one full blower’s worth of electricity.

Final Squeeze Roller Design

Soft polyurethane rollers wick the last film without pressure marks. Glass exits bone-dry, ready for spacer application in under 20 seconds.

How Much Floor Space and Utility Cost Are You Willing to Accept?

Big European brands swallow 12 meters of floor. Asian lines squeeze into nine yet still recycle water. Every square meter costs rent, and every liter of fresh water adds to the bill.

Compact Footprint with Modular Extension

The core unit measures 8500×2500×3200 mm. Add a 2-meter exit conveyor only when pairing with robots; otherwise keep it tight.

Water Recycling and Power Consumption

Built-in filtration returns 60 % of rinse water. Total draw sits at 28 kW average, quiet enough at 78 dB to run beside offices.

Noise Level under OSHA/CE Limits

Sealed blower housings keep sound below 80 dB with international certifications. Workers chat without shouting, a small win that keeps turnover low.

What Automation Level Matches Your Labor Budget?

Manual dial tweaks waste minutes per thickness change. Sensors and PLC memory shave those minutes into seconds. Remote access fixes faults before the next shift starts.

PLC + Touch-Screen Parameter Memory

Store 50 recipes. Switch from 6 mm to 19 mm in one tap; brushes lift automatically.

Auto Thickness Detection Sensors

Laser gates read ±0.1 mm and adjust roller gaps. No operator guesswork, no crushed thin glass.

Remote Diagnostics via IoT Module

4G connection lets factory techs log in from headquarters. Last month a Dubai plant fixed a pump alarm in 12 minutes without flying anyone out.

How Important Are After-Sales Support and Spare Parts?

Brushes wear, pumps clog, belts stretch. Stock in Rotterdam and Dubai means next-day air freight. Two-year warranty plus five-year cylinder coverage beats the usual 12 months. lf you have any questions, please leave Wentrica a message.

Global Stock of Wear Items

Nylon brushes, squeeze rollers, and DI resin ship from regional warehouses. No six-week waits from China.

24-Month Warranty + 5-Year Cylinder Guarantee

Cylinders rarely fail, yet the extra coverage removes worry. Factories budget repairs at zero for half a decade.

On-Site Installation and Training Package

Three-day setup includes foundation checks, water quality tests, and operator drills. New lines hit full speed by day four.

Why Choose Wentrica’s High-Efficiency Horizontal Glass Washing Machine?

Match the six factors above to one model and the choice clarifies. Jumbo size, gentle Low-E care, spot-free drying, small footprint, smart controls, and stocked spares all live in this single horizontal washer. Request a quote today and claim the free DI water test kit while supplies last.

FAQ

Q1: Can the washer handle 3 mm thin glass without breakage?

A: Yes, auto thickness sensors and soft polyurethane rollers adjust pressure to prevent cracks even at 3 mm.

Q2: How often do brushes need replacement?

A: PA1010 nylon lasts 2–3 months at eight-hour shifts; keep two spare sets on site for instant swaps.

Q3: Will hard water ruin Low-E coatings?

A: Four-stage DI keeps conductivity under 15 μS/cm, well below the 50 μS/cm damage threshold.

Q4: Does the machine link to insulating glass lines?

A: Height offsets and conveyor speeds sync with automatic butyl extruders and gas-filling presses.